Design Standard Product

Description of process

This help file covers these topics:

- Configuration and Design

- Navigator for PDM Configuration

- Functional Overview

Configuration and Design

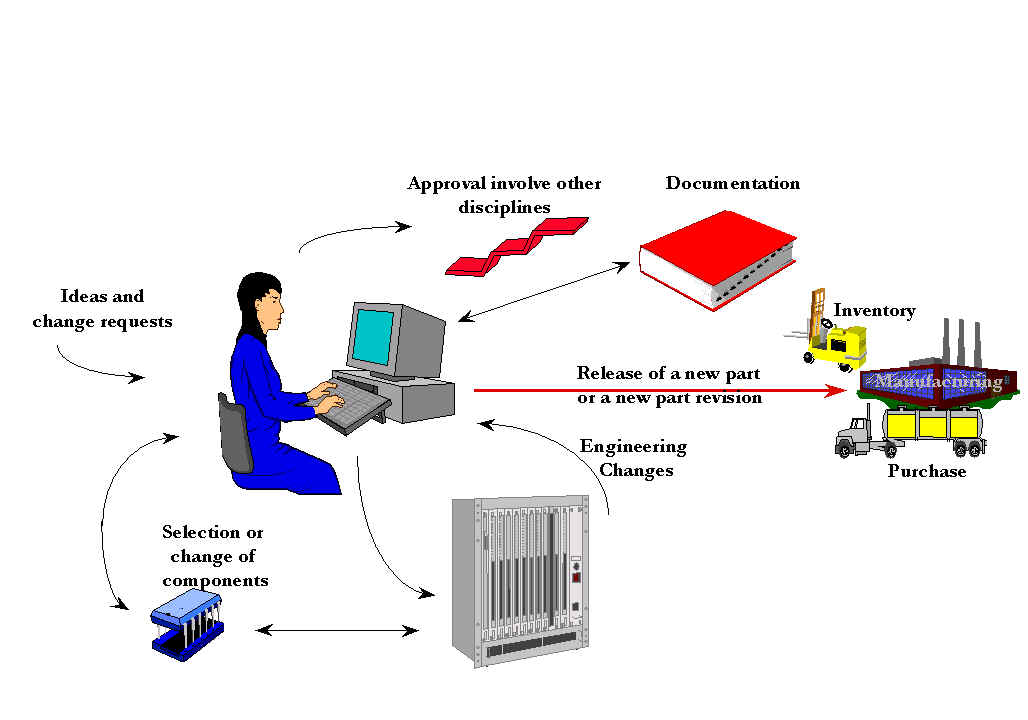

Whether you are designing new parts or creating configurations of parts designed elsewhere, your main tasks are similar.

IFS/PDM-Configuration makes everyone’s work available - in a controlled manner - to other people in the organization. Everyone sees the same information about product structures, part cost, status, documentation, etc., and spends minimum time searching for it.

By using approval routings for parts and documents, you can involve other disciplines/departments in reviewing your work at an early stage. This should lead to design or configuration changes early in the process, well before you reach the point of no return.

IFS/PDM-Configuration is designed to keep the engineer from performing the same work more than once. This design is attained through functionality that allows for the standardization and reuse of parts and documents.

IFS/PDM-Configuration supports a product configuration throughout its lifetime. When modifications are done to the original configuration and design, this module keeps track of parts, product structures, specifications, and documents for all product revisions.

Functional Overview

PDM Configuration is divided into two main parts, but there are no distinct boundaries or dividing lines. The bisection is merely a way of describing different ways of using the module. Below is a description of important functions in the system. The list is organized sequentially according to the navigator.

Products and Models

- Complete product and product model catalog.

- Fast access to additional, detailed product information.

Functions

- You see a complete overview of where parts and functions/systems are used in the entire product model range.

- Functions/systems can be organized hierarchically.

- Functions/systems can be connected to part revision(s) in the product structure in order to create specialized views of the structure, e.g., ‘plumber’ view or ‘electrician’ view.

Engineering Part

- Parts are classified and indexed, regardless of revisions.

- Characteristics can be connected to an engineering part.

- Several revisions can be created from one engineering part.

- A manufacturer survey shows possible manufacturers of the engineering part.

- Alternative parts can be registered.

Engineering Part Revisions

This is the cornerstone of the module where information about engineering part revisions is stored.

- Document references include full revision control for parts and documents.

- Standard documentation requirements can be assigned to a part class, tailored for each engineering part revision.

- Approval routings can include electronic signatures.

- A part development journal keeps track of all important status changes.

- The pre-release checking of a part can be customized.

- A Part Journal report – a complete survey of all important status modifications – provides the what, when, who, and why for each change.

- A historical document survey shows the combinations used for revisions of parts and documents.

Product Structure

Parts can be organized as a hierarchical product structure in which several powerful utilities can provide:

- Information about where a part is used and what it consists of.

- A complete multilevel product structure on-screen.

- Activation of the product structure to freeze the design and to enable use of standard product structure modules.

- Part cost calculations for a complete product structure.

- Characteristics attribute calculations for a complete product structure, e.g., total weight.

- Single and multilevel product structure reports.

- A product structure difference report, i.e., the differences between two product structures.

Characteristics

- Dynamic templates are used to handle all characteristics attributes.

- A characteristics template can be connected to a part and given values accordingly.

- A customizable summary of characteristics specifications is shown for each part.

- A powerful best fit search enables you to enter "ideal values" and get a percentage for parts in the characteristics class that come close to the numbers you entered. This means that, if you search for all blue brackets made of steel with a length equal to 12 centimeters and a height equal to 14 centimeters, you will get a list of all blue steel brackets ordered by a hit ratio.

Change Management

- Survey of all change requests for a complete product configuration or a part.

- Survey of all change orders that result from one or more change requests.

- Features for splitting a change order into manageable actions required by the engineering change.

- Summary of change orders in different statuses for different periods.