Generate Work Order

In order to automatically generate work orders from PM actions you need to specify one or several generation criteria on the PM action revision (Preventive Maintenance action revision). The criteria can be calendar, event or condition-based. You can use one type of criteria, or combine different types of criteria on one PM action. To generate work orders for the PM action you need to run the different generation routines used for generating calendar based, condition based and event based work orders. Work orders can also be manually generated directly from the PM actions, regardless of the generation criteria. Work orders will only be generated from active PM action revisions.

PM actions always generates work orders. A PM action can either be generated into a work order of its own or be grouped and/or merged together with other PM actions into the same work order. For PM Actions to be grouped into the same work order, they should all belong to the same PM Group identity and also fall due at same time. If so they will be generated into work tasks within the same work order.

For PM Actions to be both grouped and merged into the same work order they, except the requirements for grouping, also need some other things in common. They all need to have a merge flag set; they all need to have same requirements for material and resources (personnel and tool/equipment) and they could just have one line planned work list line. If so they will be generated into work task steps within the same merge work task on the work order.

PM actions open for group/merge can also apply to an already available work order as long as the work order has been marked up with same PM Group identity and is accepting other PM actions to connect. There are also some other requirements to be fulfilled on the work order; it should not yet have been started, not have any connections to other work orders, not have other specific requirements that differ from the PM actions and it should fall due at same time.

When a work order is generated, all information on the PM action is transferred to the generated work order, such as object identity, action, maintenance organization, jobs and templates, material requirements, purchase requisitions created, resource requirements, documents etc.

Note: If Copy Schedule/Planned Dates to WO checkbox is selected, the scheduling information of jobs and work lists of each PM line and the dates in the maintenance plan line will be copied to relevant fields when generating a work order.

Calendar-based generation

For PM actions that should generate work orders on a regular basis you would use calendar criteria to define when to start generating work orders, and how often. You can also schedule and plan jobs and work lists for the lines generated in the preventive maintenance plan for a PM action.

To generate work orders from calendar based PM actions you need to run the calendar generation routine. To start the routine you need to specify for what time period you wish to generate work order. You can also limit the generation by defining for which maintenance organization, group of objects, PM group, priority or action you wish to generate work orders for. PM actions that fulfill these criteria will generate work orders.

The calendar generation can be run as often as you wish. You can also generate work orders as far ahead of time as you wish. Longer planning time allows you to analyze resource requirements early and coordinate the maintenance activity with other activities.

If the PM action is set to Performed Date Based Yes, the maintenance plan is dynamic and will be updated based on the latest performed work orderís actual completion date.

Event-based generation

If you wish to generate work orders based on a certain type of event such as 'Yearly shutdown', 'Power outage', 'Breakdown', 'Revision', etc. you can use the event based generation criteria.

When you create a new maintenance plan with event-based generation, you need to specify after how many event occurrences the PM action should start generating work orders, and specify with what event interval a work order should be created thereafter, for example every second time.

To generate work orders for event based PM actions you need to report that a certain event has occurred. As this is done, the event generation routine starts and work orders will be generated from the PM actions that uses the reported event as a generation criteria. Note that the event interval on the PM must match the event sequence.

Condition-based generation

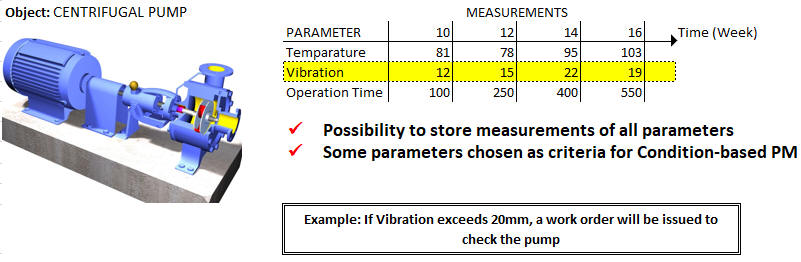

In situations where you wish that a certain condition of the equipment object should determine when work orders should be generated, you can use condition based criteria. For example, you can use a condition based PM so that a work order is generated to inspect a machine if the machine's measured temperature rises above 100 degrees. Or a work order is generated to lubricate a machine when it has run for 40 hours.

In order to create a condition based PM action, a parameter must have been defined and connected to the object ID. A parameter can measure one of two types of values; Accumulated or Limit values. An accumulated parameter can for example be 'Operation time' or 'Produced quantity'. A limit parameter can be 'Temperature', 'Oil level', 'Pressure', 'Water flow', etc. On the PM action you define what values are outside the acceptable for the object's parameter.

To report the condition of an object, readings must be done and the object parameter's measurements must be reported.

An example of condition-based PM-action generation for a pump is shown in the figure below. Measurements are taken for some parameters at certain time intervals. To handle the readings you can define a calendar criteria on the same or a different PM action.

If any cumulative criteria is registered, one condition line is shown on the Maintenance Plan tab even before any measurement is registered. You can manually generate work orders having this line only. When two or more accumulated measurements are registered, it generates a condition based forecast PM plan by calculating the average use per day under the assumption of linear use of the equipment object. When the condition generation routine is started, work orders will be generated if a recorded measurement falls outside the acceptable limits defined on the PM actions.

IMPORTANT: Upon registering accumulated measurements, the condition based forecast PM plan will be regenerated accordingly. The user can choose to run the regeneration as a background job by setting the system parameter PM_CON_PLAN_SYNC to BATCH. The Plan Out of Sync flag in the PM Action/Condition tab will indicate if the condition based forecast PM plan is in conflict with the latest measurement entered for the object. When the condition based forecast PM plan is in conflict, it will not be allowed to generate Work Orders from the affected PM Action. If the parameter PM_CON_PLAN_SYNC is set to ONLINE, the regenerate plan process will run immediately, and this might take a few minutes.

If accumulated condition-based PM action is set to Performed Value Based = Yes, the Plannned Values of the maintenance plan will be recalculated and adjusted based on either;

- The Last Measurement at Maintenance, or

- The Predicted Value at Maintenance.

However, the Due (planned) dates will be predicted under the assumption of linear use of equipment.

The Last Measurement at Maintenance

Here, the Planned Values will be calculated by adding the maintenance interval to the measurement at maintenance (latest measurement at the time the last work task is completed).

| Next planned value = Value at Maintenance + PM Interval |

For example;

| Date | Time | Measurement |

| 2019-May-11 | 22:00 | 200 |

| 2019-May-12 | 14:00 | 250 |

| 2019-May-13 | 20:00 | 300 |

| Work done time | : 2019-May-12 18:00 |

| Maintenance interval | : 200 |

| Value at maintenance | : 250 |

| Next maintenance at | : 450 |

The Predicted Value at Maintenance

Here, the Planned Values will be calculated based on a predicted value at maintenance. There are two formulas to predict the Value at Maintenance.

Formula 1 - If the work finish date is between two measurements, the estimated value at maintenance will be derived using interpolation.

Formula 2 - The Running Average is calculated based on the average usage per day under the assumption of linear use of the equipment object.

| Next planned value = (Actual Last Work Task Completion Date - Previous Measured Date) * Running Average + Previous Measured Value + PM Interval |

Note: The Running Average is calculated based on the average usage per day under the assumption of linear use of the equipment object.

The Planned Values will be calculated based on above formulas only when accumulated condition-based PM action is set to Performed Value Based = Yes. User has the option of choosing which method to use to get the Value at Maintenance, through the Condition Forecast Configuration in the PM action/General tab. The DEFAULT value will be set as Last Measurement at Maintenance.