Statistical Process Control (SPC)

With statistical process control (SPC), you can:

- Create Xbar and R, Xbar and S, X and MR, np, p, c, and u control charts.

- View and analyze control charts graphically.

SPC is a philosophy that emphasizes the use of statistical techniques, such as control charts, in all areas of a company to make continuous improvements in quality and productivity by reducing variation in processes.

SPC uses control charts to analyze a process or its outputs and take appropriate actions to achieve and maintain a state of statistical control. A process is in statistical control (“in control”) when all special causes of variation have been eliminated and only common causes remain, i.e., observed variation can be attributed to a constant system of chance causes. A process in statistical control can be described by a predictable distribution.

Some of the important benefits of using SPC and the corresponding control charts are:

- Control charts are effective tools to understand process variation and help achieve statistical control. They provide reliable information on when action should or should not be taken (over adjustment). The primary goal is defect prevention, as opposed to defect detection.

- A process in statistical control is predictable. Thus producer and customer can rely on consistent quality levels and stable cost to achieve that quality level.

- Control charts provide a common language for discussing the performance of processes.

- Control charts give a good indication whether any problems are likely to be corrected locally or require management action, since they distinguish special causes of variation from common causes.

Several statistical tests (alarm rules) can be used to determine whether a control chart is "in control". A predefined battery of alarm rules has been implemented in IFS/Quality Management – Statistical Process Control. One or more of these alarm rules can be activated. If an alarm rule violation occurs for an activated alarm rule, information about the alarm rule violation is displayed in the control chart page.

- Out of Specification: If selected, indicates you want to trigger an

alarm rule violation when any point in the control chart is above Inner Max

or Outer Max or below Inner Min or Outer Min.

- Above Upper Control Limit: If selected, indicates you want to trigger an alarm rule violation when any point in the control chart is above the Upper Control Limit (UCL).

- Below Lower Control Limit: If selected, indicates you want to

trigger an alarm rule violation when any point in the control chart is below

the Lower Control Limit (LCL).

- 2 out of 3 beyond 2 sigma: If selected, indicates you want to

trigger an alarm rule violation when at least two out of three successive

points in the control chart on the same side of the centerline (CL) are

beyond the 2 sigma limit.

- 4 out of 5 beyond 1 sigma: If selected, indicates you want to

trigger an alarm rule violation when at least four out of five successive

points in the control chart on the same side of the centerline (CL) are

beyond the 1 sigma limit.

- 15 at or within 1 sigma: If selected, indicates you want to trigger

an alarm rule violation when 15 successive points in the control chart are

at or within 1 sigma.

- 8 outside 2 sigma: If selected, indicates you want to trigger an

alarm rule violation when eight successive points in the control chart are

outside +2 or -2 sigma.

- 8 below or above the centerline: If selected, indicates you want to

trigger an alarm rule violation when eight successive points in the control

chart are below or above the centerline.

- Runs up/down of length 8 or greater: If selected, indicates you

want to trigger an alarm rule violation when eight successive points in the

control chart are in ascending or descending order.

If any of these alarm rules are violated, corrective action should be considered.

There are numerous types of control charts that can be used for different situations. The picture below describes the most commonly used control charts and when to use them:

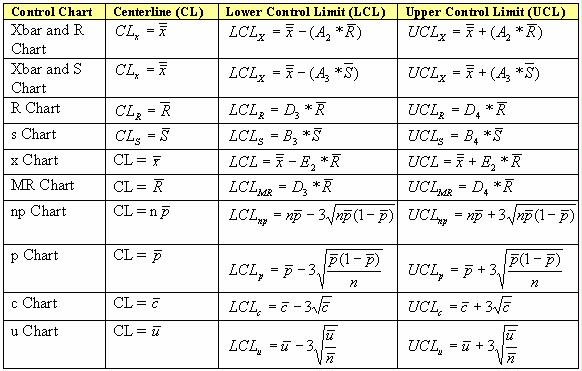

The formulas used to calculate these different types of control charts are:

|

The values for the constants A2, A3, D3, D4, B3,

B4 and E2 can be found in any Statistical Table. n =sample size, p =

(number of defective in sample) / (number of items in sample), n

![]() (sample size)*((total number of defective samples) /

(total number of samples)), c = number of defects counted in a sample, u = (number of

defects counted in a sample) / (number of items in a sample).

(sample size)*((total number of defective samples) /

(total number of samples)), c = number of defects counted in a sample, u = (number of

defects counted in a sample) / (number of items in a sample).

Control charts are typically displayed graphically.