Scheduling with Maintenance Planning Board

This description is divided into following sections:

- What is Maintenance Planning Board (MPB)?

- The Integration between Maintenance Planning Board and IFS Cloud

- Functional Dependencies

- Scheduling Concepts

- Scheduling Work Orders/Preventive Maintenance with Maintenance Planning Board

- Load Work Orders and PM Occurrences to MPB

- Scheduling Status

- Scheduling Methods

- Scheduling Logic

- Resource Allocation based on Constraints

- Resource Allocation ignoring Constraints

- Resource Allocation with Resource Groups

- Scheduling Critical Work

- Scheduling using Equipment Object Accessibility

- Scheduling Multisite Work Tasks

What is Maintenance Planning board?

Maintenance Planning Board (MPB) is mainly about scheduling Work Orders or/and Preventive Maintenance on sites, while assigning or reserving Resources, using a Scheduling client. This only considers the constraints placed by Work Orders/Preventive Maintenance and Resources that are actually loaded to the Maintenance Planning Board at a given time and not all the Work Orders/Preventive Maintenance and Resources available at the site. It also depends on whether the Resources used for the Work Tasks/ PM Work Lists have finite/infinite scheduling capacity. If the IFS/Operational Plan is used scheduling can be performed by considering the equipment object accessibility as well, which is derived from Operational plans. The scheduling process is supported by a graphical representation of Work Order/PM action occurrences, Work Task/Work List, Resources, calendars, etc. This powerful graphical interface allows you to work with the schedule interactively. You can move the Work Tasks/ Work Lists and Resources along a timeline using drag-and-drop and schedule them to meet your requirements. The changes you make can then be saved back to the database and the changed Work Orders and PM actions will be updated accordingly. Note that the data presented in the Maintenance Planning Board is not constantly synchronized with the data in the database. You need to reload data to the Maintenance Planning Board to see the latest data from the database at a given time.

The Integration between Maintenance Planning Board and IFS Cloud

The Maintenance Planning Board solution provides below functionalities:

- Scheduling stand alone Work Orders, Work Order Structures and Active PM action occurrences in PM maintenance plan of a site/ site network.

- Scheduling Resource Breaks and project connected stand alone Work Orders.

- Defining Resource Groups with infinite or finite capacities and performing infinite or finite scheduling of maintenance and resources.

- Defining critical work on Work Tasks/PM Work Lists and prioritize scheduling of critical work.

- If IFS/Operational Plan is used, visualization of operational plans and scheduling Work Orders/PMs based on object accessibility.

- Visualizing and Scheduling maintenance in multiple sites in the same client using Maintenance Planning Board for Planning Network.

Functional Dependencies

The following IFS Cloud components are used for the Maintenance Planning Board solution;

- IFS/MPBINT

- IFS/WO or/and IFS/PM

- IFS/OPPLAN (Optional)

Furthermore, the following solutions are not applicable to be used together with the Maintenance Planning Board solution;

- IFS/Planning Scheduling Optimization

Scheduling Concepts

- A Work task/PM Work list is the smallest schedulable unit.

- Maintenance Persons and Tool/Equipment are Scheduling Resources in IFS Cloud.

- The scheduling inside Maintenance Planning Board is based on:

- Scheduling requirement on Work Task/PM Work List and Work Order/PM action

- Resource availability

- Material availability

- Equipment Object accessibility (If IFS/Operational Plan is used)

Scheduling Work Orders/Preventive Maintenance with Maintenance Planning Board

In order to schedule a Work Order/Preventive Maintenance using IFS/Maintenance Planning Board, the Work Order Site must be MPB enabled.

Load Work Orders and PM Occurrences to MPB

Maintenance Planning Board is opened using IFS/Maintenance Planning Board or IFS/Maintenance Planning Board for Planning Network. Work Orders with status Fault Report, Work Request, Observed, Under Preparation, Prepared, Released and Work Started can be loaded into the MPB. However, if these Work Orders contain Work Tasks in Work Done status and above, those Work Tasks are not loaded into the MPB. Furthermore when loading Work Started Work Tasks, it always overrides the Planned Start Date with Actual Start Date and Planned Finish Date with Actual Start Date + Duration inside MPB. Thereby, it will not be possible to Schedule or Unscheduled the Work Started Work Tasks inside MPB.

Preventive Maintenance actions with Active status can be loaded into the MPB to schedule Preventive Maintenance occurrences. If IFS/Operational Plan is used, it is possible to load Operational Plans with statuses Active and Under Preparation. You can load sub set of stand-alone Work Orders, Work Order Structures and Preventive Maintenance occurrences based on the required filter criteria on IFS/MPB Load dialog box.

Scheduling inside Maintenance Planning Board provides an optimized schedule to satisfy all constrains, based on scheduling requirements defined on Work Tasks / Work Lists, Resource availability, Material availability and Equipment Object accessibility. Saving back the schedule updates the Planned Start and Finish Dates of the Work Tasks, Work Lists, Work Orders or/and PM action occurrences and updates the Resource allocations for each Work Task or/and Work List. It also updates the scheduling status of Work Task or/and Work List, Work Order or/and PM action occurrences as well.

-

Scheduling requirement on Work Task/PM Work List and Work Order/PM action

Set of information defined on Work Task/PM Work Lists/PM action such as Earliest Start/ Fixed Start Date on Work Task and PM action occurrence, resource requirement defined on Resource Demands, Dependencies between Work Tasks/Work Lists are considered as scheduling requirements which must be satisfied when scheduling. Furthermore if IFS/Operational Plan is used, then the information such as Scheduling Inside One Maintenance Window, Scheduling Obstructive Work Tasks/Work Lists are considered as scheduling requirements during certain scheduling scenarios. The Latest Finish Date on Work Task or PM occurrence is considered as scheduling objective that is to be achieved during scheduling. However, if the order can not be scheduled before the Latest Finish Date, it is indicated as a Tardy Work Task/ Work List. Also there are resource constrains defined on Work Task/ Work List i.e. Maintenance Organization, Resource Groups, Resource and Team etc. The resource allocation is done to satisfy this resource constrains as well.

-

Resources availability

Persons, Person Groups, Tool/Equipment and Tool/Equipment Groups are considered as Resources in Maintenance Planning Board. All the resources that are defined as maintenance resources for the given site is loaded into MPB and represent the resource structure similar to the structure in Resource Navigator. If MPB is loaded for planning network, the resource structure is duplicated for each site if the resource groups are connected to multiple sites. Resources are allocated to Work Task/Work List based on defined constrains on Work Task/Work List and scheduling requirement on Work Order/PM. Maintenance Organization, Person Group, Person and Team are considered as person constraints. The constraint for tool/equipment are Maintenance Organization, Tool Group and Tool ID. However, it is possible to allocate resources breaking constrains by manually dragging resources to the task roles as well.

Resource availability is connected with calendar. Individual person can be connected to a calendar in IFS/Resource Navigator. MPB uses this calendar to decide persons availability. If the person calendar is not available, then the maintenance organization calendar which is the calendar that is connected to person's primary employment is taken for scheduling. For tools, the calendar connected to the tool/equipment is considered and if it is not available maintenance organization calendar which the tool is connected is considered. Resource breaks are also used to define unavailability of resources.

Furthermore, there is an infinite and group resource concept. i.e. person or tool group can be defined as a resource and can be defined with infinite capacity or finite capacity. Then, it will be possible to allocate resource groups as an allocation for task roles. If the resource group has infinite capacity, it is possible to allocate any number of Work Tasks/PM Work Lists on infinite resource groups, at a time.

-

Material availability

Part's availability can be defined as Infinite, Finite (within a specific lead time), or Always Finite. Availability of material is considered in MPB, if the material line in the Work Order/PM is connected with a Work Task/Work List and the material is defined as finite or always finite in IFS/Inventory Part. The parts with infinite availability are ignored by MPB. For parts with finite availability, MPB checks for the required amount as it schedules. The required amount can be comprised of an existing supply or from a new supply within the part's lead time. After the part's lead time, MPB assumes the part has infinite availability. For parts that always have finite availability, the required amount needs to be available to schedule a Work Task/ Work List. As MPB schedules, it records the quantity and the date and time at which the material is consumed.

-

Equipment Object Accessibility

This is applicable only if IFS/Operational Plan is used. Object accessibility is the time plan where the object is not used by any operational activities defined in IFS/Operational Plan. This is derived from Active operational plans connected to the Equipment Object structure and Operational Mode connection between Equipment object and Operational plans. For more information refer Scheduling with equipment object accessibility. Object accessibility is only considered when Scheduling Obstructive Work Tasks/Work Lists in Work Order/PM or when the Work Order/PM action occurrence need to be Scheduled inside one maintenance window. Work Tasks can have different object accessibility based on the connected object to the Work Task. If the Actual Object is available on the Work Task, that object is considered to derive the object accessibility. If the Actual Object is not available, the Reported Object is taken. When all the Tasks of the Work Order needs to be scheduled inside one maintenance window, then the overall object accessibility is derived from accumulation of the object accessibility of all Work Tasks of that Work Order. For PM Work Lists, the object accessibility for Work Task is taken considering the object connected in the PM header.

There are different scheduling statuses for Work Tasks/PM Work Lists inside MPB as well as in IFS/Prepare Work Order or IFS/PM Action. There is no one to one match between statuses, but there is a logical relationship between them.

Inside IFS/Prepare Work Order or IFS/PM Action, a Work Task/PM Work List has scheduling statuses Need Rescheduling, Scheduled and Unscheduled. The status Need Rescheduling is for newly created Work Tasks/PM Work Lists or when there is a modification of data in any Work Task/PM Work List or Work Order/PM which affects on MPB scheduling. If the Work Task/PM Work List has the status Scheduled, then the Work Task/PM Work List is scheduled in MPB and resources and planned dates are allocated. If the Work Task/PM Work List is Unscheduled, this means that there are no enough resources to schedule or any of the scheduling requirements or constrains are not satisfied during MPB scheduling. It also can be due to manual un-scheduling of orders.

Work Order/ PM action occurrence level scheduling status could have

Need Rescheduling, Resolved, Unresolved and Unresolved (Tardy).

Need Rescheduling is for newly created Work Order/PM action occurrences

or when there is a modification of data in any Work Task/Work List or Work Order/PM

which affects on MPB scheduling. Work Order/PM action become Resolved,

if all the Work Tasks/Work Lists are scheduled and met the Latest Finish Date

of the Work Task/Work List. Unresolved indicates that there are one or

more Unscheduled Work Tasks/Work Lists. Unresolved (Tardy) indicates

that all Work Tasks/Work Lists are scheduled but there are one or more Tardy

Work Tasks/Work Lists which do not meet the Latest Finish Date of the Work Task/Work

List.

Inside MPB, Work Task/Work List can have Incomplete,

Unscheduled, Resources Assigned, Scheduled, Firmed Planned,

Work Started, Need Rescheduling and/or Tardy status. A Work

Order/PM action occurrences or Work Task/Work List can have a valid combination

of these statuses and indicates in show dialog box of each item with crossed

mark. If there are no Work Task/Work List in the Work Order/PM action

occurrences, then none of the statuses are crossed. The statuses can be described

as below;

- Incomplete: There is no constraint defined in Work Task/Work List (i.e. Maint Org, Team or no Resource Demand) or the Maint Org site is not any of the MPB loaded sites.

- Unscheduled: There is no Planned Start/ Finish Date and assigned resources for the Work Task/Work List at a given time; i.e. during the load or after rescheduling/unscheduling Work Tasks/Work Lists.

- Resource Assigned: There is no Planned Start/ Finish Date but there are assigned resources for the Work Task/Work List at a given time i.e. during the load or after rescheduling/unscheduling of resources.

- Scheduled: This is applicable for Work Lists in PM action or Work Tasks at status New, Under Preparation, Prepared and if there are Planned Start/ Finish Dates and assigned resources.

- Firmed Planned: This is applicable for Work Tasks at the status Released and if there are Planned Start/ Finish Dates and assigned resources.

- Work Started: This is applicable for Work Tasks in the status Work Started and if there are Planned Start/ Finish Dates and assigned resources. When loading Work Started tasks, it automatically set the Actual Start Date of the task as the Planned Start date and Actual Start Date plus duration as the planned Finish Dates, inside MPB.

- Tardy: The Work Task's/Work List's Planned Finish Date is later than its Latest Finish Date.

- Need Rescheduling: The Work Task/Work List need to be scheduled

in MPB. This check is cleared during rescheduling/un-scheduling except in

Work Tasks at Work Started status.

As and example, if you load new Work Order with Work Task at the status 'New'

and if it has Planned Start and Finish Date which is defined in the Work Task

manually, then MPB loads it while assigning the possible resources and Work

Task is indicated with status combination of Need rescheduling and

Scheduled. Once you reschedule the Work Task then the Need rescheduling

cross mark is cleared and Work Task become Scheduled. If you drag the work beyond

the Latest Finish Date of the Work Task, then the Work Task gets the combination

of Scheduled and Tardy. If you unschedule the Work Task by maintaining

resource assignment, then the Work Task gets the status Resource allocated.

Work order always get the combined statues of all Work Tasks. In the save back

process, if Work Task does not get a Planned Start/Finish Dates or resource

allocation from MPB, then Work Task in IFS/Prepare WO, become Unscheduled in

Work Task line. If Work Task gets Planned Start/Finish Dates and resource allocations

from MPB, then Work Task become Scheduled.

There are two different methods of scheduling.

1. Automatic scheduling

Automatic scheduling can be performed on individual Work Task/Work List, Work Order, PM action occurrence or on any collection of Work Order or/and PM action occurrence. It is also possible to perform automatic scheduling on resources, i.e. Persons, Tools or any collection of resources. Automatic scheduling provides three scheduling modes;

- As soon as possible: i.e. to schedule Work Task/Work List closer to the Earliest/Fixed Start Date or present time as much as possible.

- As late as possible: i.e. to schedule Work Task/Work List closer to the Latest Finish Date.

- As late as possible with compress: i.e. to schedule Work Task/Work List closer to the Latest Finish Date and the compress function shifts Work Tasks/Work Lists from right to left, closer to their preceding Work Tasks/Work Lists. This tends to minimize the processing time for an Work Task/Work List.

If project connected stand alone Work Orders are to be scheduled by selecting a project activity, project or a collection of projects, the order start date can be selected as Work Task Earliest/Fixed Start Date, Activity Early Start Date or Activity Late Start Date. Project connection between Work Orders in Work Order Structure is neglected by MPB.

Scheduling of set of object (Work Orders, PMs, Resource Break etc.) can be performed on selected actions if it is applicable, i.e.

- Schedule selected unscheduled objects

- Schedule selected scheduled objects

- Schedule selected firm planned objects

- Schedule selected objects that need rescheduling

There are two options for resource assignment when scheduling. i.e. Maintain Resource Assignment and Re-assign Resources. If maintain resource assignment is selected, then the orders are scheduled using assigned resources. If reassigned resources option is selected, then it removes existing data and re-assigned resources based on constrains.

2. Manual Scheduling

Work Tasks/Work Lists, Work Orders/PM action occurrences or resources can be manually scheduled by using Insert and Drag & Drop options.

- Drag and Drop: This can be performed by using Right-click option drag and drop. This action move the Work Order/PM action occurrence, Work Task/Work List where there is available resource capacity to perform the work which satisfy all the constrains and scheduling requirement.

- Insert: This can be performed by using Left-click option drag and drop. This action insert the Work Order/PM action occurrence or Work Task/Work List where you drop it and maintaining the same resources and other orders will be pushed out.

When constructing a schedule, many different steps are taken using different algorithms. First, material availability and resource assignment options are evaluated. Then, the earliest and latest possible start times for all Work Tasks/Work Lists are determined. Based upon a selected priority rule, these time values are used to sort the Work Tasks/Work Lists in the order in which they will be scheduled. The Work Tasks/Work Lists are then scheduled forward with the finite capacity constraints of the materials and resources. After scheduling, there are some optimization techniques that can be chosen. As late as possible scheduling mode moves all Work Tasks/Work Lists as close to their Latest Finish Date as possible. With Compress option moves Work Tasks/Work Lists as close together as possible from left to right. There are some key objectives to accomplish when constructing a schedule by MPB:

- minimize tardiness

- minimize the working progress of orders

- minimize the lead time of schedule (closeness to the Earliest Start or Latest Finish Date based on scheduling mode)

- resource load balance among infinite resources, i.e. in case more than one infinite resource is available to choose from MPB will give priority to the least loaded resource

- primary resource consideration

Resource Allocation based on Constraints

Selection of allocations are done based on the defined constraint on the Work Task/Work List and on demand lines. Resource also should belong to the maintenance organization site mentioned in the Work Task/Work List.

|

Resource |

Constraints used for Resource selection |

|

Person |

Maint. Org on Task, Team on Task, Person Group on Demand line, Person on Demand line If a person resource is assigned on a task role, it should satisfy all above constrains, i.e. person should belong to the mentioned Maint Org, team, person group and if the person ID is mentioned in the task demand, then the same person should be allocated who does satisfy other constraints as well. |

| Tool |

Maint. Org on Task, Tool Group on Demand line, Tool ID on Demand line Similar to the person, allocated tool resource should satisfy all above three constraints |

|

Person Group |

Person Group

on Demand line When allocating a person group as a resource, it should be the same resource group mentioned in the demand line or subgroup of the mentioned resource group in the demand line. |

|

Tool Group |

Tool Group

on Demand line Similar to the person group, when allocating a tool group as a resource, it should be the same resource group mentioned in the demand line or subgroup of the mentioned resource group in the demand line. |

Resource Allocation ignoring Constraints

It is also possible to allocate resources ignoring constraints. A resource which does not satisfy above constraints can be manually dragged and drop in to a role of Work Task/Work List item. If the task is automatically scheduled selecting 'Maintain Resource Assignments' then MPB schedule the Work Task/Work List maintaining the same assigned resource. This is applicable for all resource types, i.e. Person, Person group, Tool, Tool group.

Resource Allocation with Resource Groups

Resource groups are loaded and displayed; in MPB as a structure which is defined in Resource Navigator. Person group or Tool group is considered as a resource inside MPB, if it is selected for Use as Resource. Resource group can have a scheduling capacity and a calendar. If the Infinite flag is selected, then it is possible to allocate any number of Work Tasks/Work Lists on to that resource group.

Maint. Org. Independent

Maint. Org. is one of the constrain that consider when it’s come to scheduling resources. To ignore this constrain user can enable the option Maint. Org. Independent for the selected resource group. After enabling this option user can schedule any resource within the site ignoring the Maintenances organization of the resource. This information is valid, if the site is enabled for Work Order scheduling using Maintenance Planning Board.

A Work Task/Work List is considered as critical work based on the work type, criticality of equipment object connected to the Wok Task/PM action and the priority on Work Task/PM action. Critical work basic data need to be defined in IFS/Work Order PM Basic Data page. Inside MPB, there is a special way of handling Critical Work Tasks and Work Lists

- It is possible to give the priority to critical work during automatic scheduling by selecting the Prioritize critical work

- Drag and drop action cannot be performed on Work Tasks/Work Lists, if it is a critical work and if it become tardy with the action. When performing 'insert' on Critical Work Task/Work List, it does not move other Critical Work Tasks/Work Lists, instead it moves other Work Tasks/Work Lists.

- Also if you need to replace one Critical Work Task/Work List from another Critical Work Task/Work List, user must first perform insert or unscheduled on Work Task/Work List, which needs to be replaced and then insert the WO which need to be rescheduled.

- If a Critical Work Task/Work List become tardy, then it is indicated in a red label below the MPB client.

If a Critical Work Task/Work List become tardy, then during the save back, MPB act as below based on the basic data setup defined in 'Save Tardy Critical Work' in IFS/Maintenance Planning Board Basic data setup;

- Work Order/PM occurrence's schedule does not save back to database and information message is displayed or

- Work Order/PM occurrence's schedule is saved back with a warning message or

- Work Order/PM occurrence's schedule is saved back without a warning

Scheduling using Equipment Object Accessibility

In certain scenarios, some maintenances are not possible to perform during the equipment object is used for its productive operational activities. Equipment object accessibility in MPB is the time plan where the Object is not involved with its operational activities. If IFS/Operational Plan is used, then there is a possibility to define operational plans for the equipment object structure in IFS/Operational Plan. Operational Modes are used to derive object accessibility against the operational plan. Operational Modes can be defined in IFS/WO PM Basic Data and can be connected to individual equipment objects and operational plan items in the Operational plan. MPB loads all active operational plans which is connected to equipment object structure, if there are any Work Task/ Preventive Maintenance connected to an object in the object structure is/are loaded to MPB. In MPB, object inaccessible time is derived using the operational plan and operational mode.

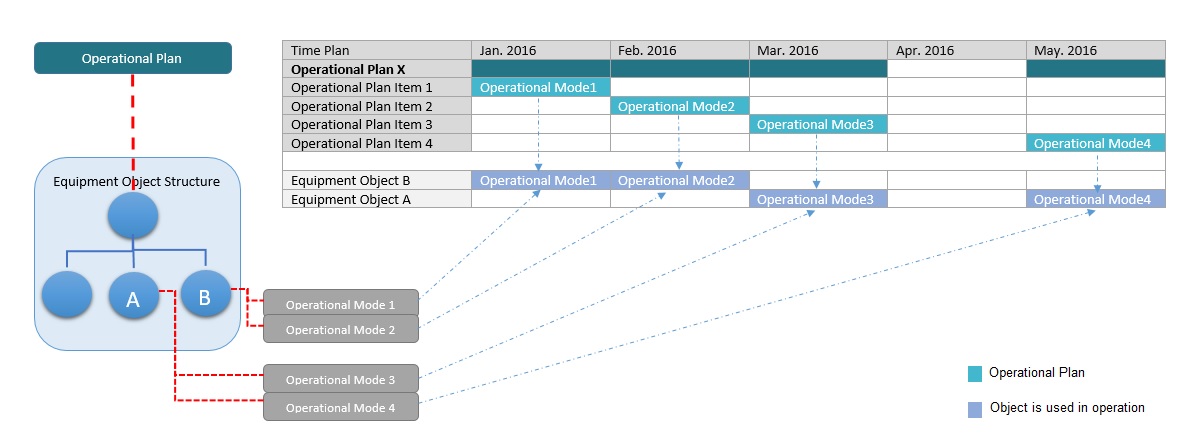

As an example, in the below diagram object structure is connected to the operational plan X. Object A is connected to operational mode 1 and 2, while the Object B is connected to operational mode 3 and 4. Operational plan items in the Operational plan X are connected with Operational mode 1,2,3 and 4. MBP derives the time plan where the object is in use by operational activities using operational modes as below. There, the Object A is used for operational activities during Jan.2016 and Feb.2016 while it is available for maintenance activities from March.2016 onwards and obstructive work tasks of the Work Orders/PMs belong to this object can only be scheduled during this period. Similarly, Object B is available of maintenance during Jan.2016, Feb.2016 and April.2016 while it is in operation during March.2016 and May.2016.

Equipment Object accessibility is involved in different scenarios.

- Scheduling Obstructive Work

Scheduling Obstructive is a derived value from Safe Access value on the Equipment Object together with the Operational Status Type on the Work Task/Work List line. Example: If Safe Access is Required and Operational Status Type is Not Obstructive on the Work Task/Work List, this value is derived as Obstructive. In all other cases this value follows the Operational Status Type-value defined on the work task. During the scheduling, scheduling obstructive Work Task/Work List in Work Order/PM cannot be scheduled in a time period where the object connected in Work Task/ PM is in use by an operational activity in operational plan. The Work Order/PM Work Task/Work List that are not scheduling obstructive can be scheduled any time period satisfying other scheduling requirements and constrains.

- Scheduling Inside One Maintenance Page

The option Scheduling Inside one maintenance window can be set on IFS/Prepare WO/MPB Scheduling or/and IFS/PM action/General tab. If the Work Order/PM is selected for Scheduling Inside one maintenance page, then all the Work Tasks/Work Lists in Work Order/PM will be scheduled in a continuous time period where the object is not in use by an operational plan item. There will be no operational activities in between Work Order/PM Work List.

Scheduling Multisite Work Tasks

- Work Orders with Work Tasks from multiple sites

Work order can have Work Tasks for different Work Task sites and different maintenance organization sites. These Work Orders are handled in MPB as below;

- MPB loads all the Work Tasks inside the Work Order even if the task site is different to the WO site.

- When scheduling, it always considers the Work Task's Maint. Org site to assign resources, i.e. resources are selected from the Maint Org site of the Work Task.

- If the Maint org site of the Work Task is different than the MPB WO site, then these tasks are considered as incomplete and will not be scheduled inside MPB. However, if MPB for Planning Network is used, then if the Maint Org site is included in the planning network, the Work Task is scheduled by MPB assigning resources from Work Task's Maint Org Site.

- Work Order Structures with Work Orders from multiple sites

When using MPB single site solution, MPB does not load the Work Order Structure, if it has Work Orders from other sites and it does not allow to continue schedule for that site. However, by using MPB for Planning Network, it is possible to load and schedule Work Order Structures from multiple sites.

Scheduled Result

The planned dates of the Work Task/Work List item, scheduling status change, and resource allocations are considered as scheduled result. The schedule of Work Orders and PM action occurrences can be save to the database. The Work Order and PM action information will be updated. Allocations for each PM action occurrence will be saved and can be visualized in PM Action/Jobs and Work List page.

If a Work Task or PM action occurrence which is defined as Critical work become tardy in MPB scheduling, then it is indicated with red color label in the bottom of the window. However, there is a basic data setup to control saving back a tardy schedule on database. It can be set up in IFS/Scheduling basic data. It is possible to set to give an error, warning or allow saving by ignoring the tardy critical work. In Work Orders, if any of the Critical Work Task is tardy then the defined conditions are applicable for the whole Work Order, i.e. in basic data, if it is defined to give and error for tardy Work Order, then if at least one Critical Work Task is tardy, then schedule is not saved back for the whole Work Order.

For Work orders, if individual resources are assigned for Work Tasks, then the Work Assignments are created for each allocation. If group allocations are created, then a work assignment is not created, but it is updated in the background and when MPB is reloaded, then group allocation information will be available. For PM Actions, Work Assignments are not created, but allocations are visible in PM Action/Jobs and Work List page.

If Copy Schedule/Planned dates checkbox on Site window is selected then, during the WO generation of PM action, the schedule is transferred to the respective Work Order and Work Assignments are created for the individual resource allocations. Therefore you do not need to plan PM generated Work Orders, if they are already scheduled in MPB as a PM action occurrence. However, if grouped Work Tasks are created during WO generation, then the schedule of the task is copied but the WO scheduling status is set as Need Rescheduling. If the merged tasks are created during the WO generation, then the schedule is not copied at all.

Upon saving back the schedule, corresponding material requisition's requested date is also updated.