Multi-Echelon Planning

Multi Echelon is an integrated part of IPR and cannot be used without running IPR however in most implementations Demand Planning will also be a part of the solution.

Multi Echelon is a solution for planning upstream (central, region in the figure below) stock levels based upon the stock levels and ordering policies of the down stream sites (distribution centers). It optimizes the stock levels throughout the entire supply chain with focus to reach the target service level for the end customers.

For planning method B (order point planned) items the supply plan computed in IPR will be aggregated to the upstream echelons forecast. The IPR Supply plan is an ordering forecast that includes the calculated order date and order qty in a future horizon, this plan takes on hand qty, safety stock, order cycles and future orders in the downstream echelons into account, in short this is the forecasted future order date and order qty's.

Multi Echelon also supports parts with other planning methods that B, it supports all planning methods, other planning methods than B will result in that their 'forecast' being aggregated to the upper level site/echelon. What's considered to be the forecast is determined by demand model setting for the part in IPR, note that on all echelons apart from echelon 1 (Distribution centers) the demand model in IPR must be set to forecast if you want to use the down stream sites/echelons forecasted qty's in your planning.

In the Multi Echelon matrix setup screen you have the possibility to configure which planning methods that should be included in the multi echelon calculations, if no limits are set then all planning methods will be considered, more about this dialog later.

Setup and Configuration

Internal Supplier

To create a row in the Multi Echelon Matrix screen below a site will need to have an internal supplier defined, this is done in the Supplier screen under the Purchase folder (Application Base Setup/Enterprise/Supplier/Supplier/Purchase) in the Internal Supplier section you activate the slider and then specify the site that this supplier should be the internal supplier for. When this is done you will find the new combination in the Multi Echelon Matrix screen with the Supplier Site as the Supply site and the Supplier ID as the Source Id.

Multi Echelon Matrix

This is a screen that shows the different sites and their corresponding internal supplier you find it under Supply Chain Planning/Part Planning/IPR Planning/Multi Echelon Matrix. In this table you have one row for each site / internal supplier combination for example the first record in the table below indicates that supplier id 095211 is an internal supplier for site DM_ME any item on any site that has this supplier as it primary supplier will be considered sourced from site DM_ME thus these parts will have their 'forecast'/IPR Supply Plan added to the forecast for DM_ME (depending on the planning method for the item/site). Note its not possible to add such a Supply Site / Internal Supplier record in this dialog the dialog just shows the different site/internal supplier combinations that is made in the supplier setup screen.

| Supply Site | Source Id | Source Type |

| DM_ME | 095211 | Supplier |

| DM_ME | 0 | Flow |

The second line is an example of a Supply Site / Flow Record. This illustrates the possibility to add a separate flow from demand planning to a supply site, in the example above flow id 0 is added to the DM_ME site, the forecast on this flow in demand planning will be added directly to the forecast for the DM_ME site. This is typically used when an upstream location delivers goods directly to external customers, and you want to include that demand source to the inventory planning of the site.

The last option that you have in this screen is to configure a Multi Echelon Condition List, this is done trough a nested table that is accessible by clicking on the arrow in front of the Supply Site field this nested table is only available on Supply Site / Supplier records not on the Supply Site / Flow records. In this nested table you can add which planning methods that should be excluded from the Multi Echelon calculation. In this nested table you have to following fields

| Supply Site | Source ID | Destination Contract | Planning Method | Description |

| DM_ME | 095211 | DM | A | |

| The upstream site, the sourcing site | The internal supplier connected to the supply site | The site receiving goods from the supply site | The planning method to include | Free naming field |

The record above will mean that ONLY planning method A items on site DM that has supplier 095211 as its primary supplier, will get its forecast added to the forecast for site DM_ME. In other words this should include the planning methods that you want to include in the Multi Echelon Calculations. Each Supply Site / Internal Supplier record can have a nested table with included planning methods. If there is no table/records added for a site then all planning methods is included in the Multi Echelon Calculation.

Supplier for purchase parts

Then all parts to be included in the Multi Echelon Calculations will need to have the internal supplier defined as its primary supplier. The sourcing site is defined by the site connected to the internal supplier. You add new supplier for purchase parts in Procurement/Part/Supplier for Purchase Part. If an item as a non internal supplier as its primary supplier this items forecast will not be added to any upper level echelon forecasts.

How does Multi Echelon Work

Multi Echelon with none planning method B items will work in the same fashion as combined flows in Demand Planning, but instead of having a fixed planning hierarchy / sourcing rule for all parts on a site, using multi echelon parts will have unique planning hierarchy/sourcing rule for each part determined by the primary suppler connection of the part.

Planning method B (reorder point planned) items works in a slightly different way, here the items IPR Supply Plans will be added to the upstream forecast, these supply plans takes the on hand qty and the ordering policy of the down stream site into consideration meaning that the supply plan is the forecasted net supply demand for the down stream site. Then the sum of all these supply plans will then be the forecast for the upstream site and so on.

The figure above shows an example a Multi Echelon setup over 3 levels, only Echelon level 1 can have master flows defined in Demand Planning, if there is defined a master flow for any of the upper echelon sites, then the sites with a master flow defined will not be part of the multi echelon calculation the forecast for this site will then be the forecast from the master flow in Demand Planning. Note that parts on the sites in echelon 1 can be sourced from sites in any of the upper echelons (Region West, Region East or Central).

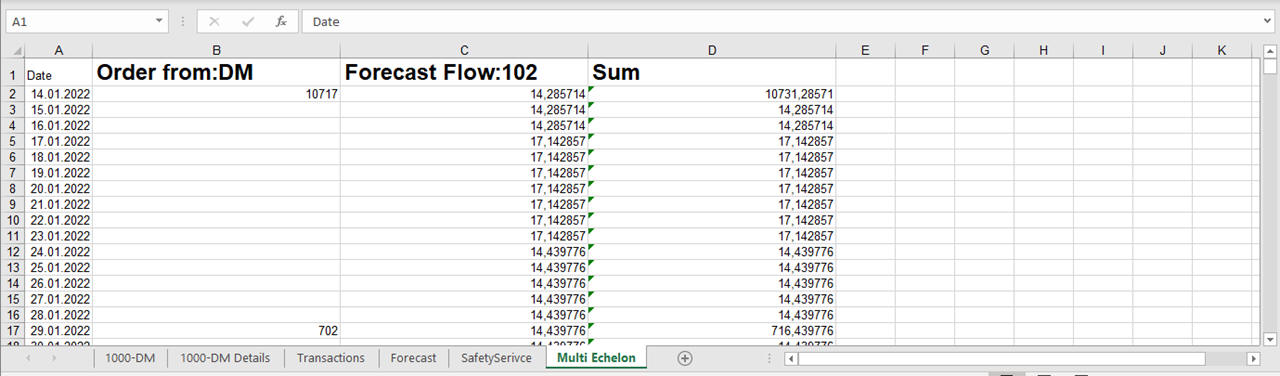

Multi Echelon Calculations in the IPR ExcelSheet

The IPR Excel sheet is expanded with 2 new tabs to explain the multi echelon calculations, this Excel sheet is accessible from the Inventory part planning data screen. The two tabs are:

Multi Echelon

This Sheet show how the resulting Multi Echelon forecast is calculated, it will be the forecast for the site/part number that is selected in IFS Cloud when ordering the Excel sheet. In the above example you can see that the upper echelon forecast (column D) for part 1000-DM is based on a IPR Supply Plan from site DM(column B) and an external flow id 102 (column C) from Demand Planning. Column D which is the resulting forecast is then the sum of the B and C column's.

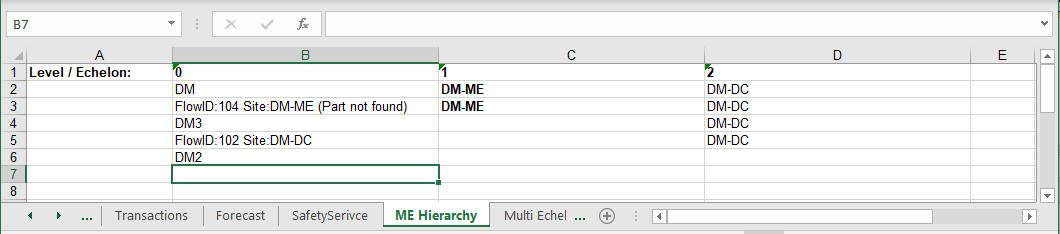

ME Hierarchy

The second tab shows the sourcing hierarchy for the site/part that is selected in IFS Cloud when ordering the Excel sheet. The sheet shows all Echelon levels in the hierarchy, the bold face level is the level/site that was selected when ordering the Excel sheet. In the above example you see that Part 1000-DM (first tab that are not visible in the figure) and how this part is sourced. The selected site DM-ME is responsible for sourcing 1000-DM to site DM, 1000-DM is not present in the external flow (104) out of DM-ME, in other works 1000-DM is not shipped to external customers directly from site DM-ME. 1000-DM is sourced directly from central warehouse DM-DC for site DM3, and its also shipped directly to external customer (flow:102) from the central warehouse DM-DC. Finally we see that 1000-DM is sourced from an external supplier on site DM2.

Results

The result out of Multi Echelon is a forecast for the upstream echelon sites where each item can have its unique set of sourcing rules, these sourcing rules are based on which primary suppliers are set for the item on the different lower level echelon sites. The resulting forecast is available in the Exported Forecast screen in Demand Planning. These forecast can be imported into Master Scheduling and MRP Spares, or used in IPR as a base for further planning on the upper echelon sites.