Remanufacturing Shop Order

A shop order of type Remanufacturing is an electronic document that authorizes the remanufacture of a specified part. The remanufacturing shop order handles the restoration of a component or product to a "like-new" condition. The disassembly of the worn-out product (core) is handled on a separate disassembly shop order (see Pegged Direct Supply section).

A remanufacturing shop order can also produce by-products, and may result in substitute parts, i.e. the receipt of another than the intended part number. When you create a remanufacturing shop order, the system creates material requirements and schedules operations. The system retrieves operations and materials according to the part, valid remanufacturing structure/routing revision and selected alternate. The alternate may also be fetched based on the lot size, or the serial number that you entered.

A remanufacturing shop order can be created manually, or from customer order and case task handover.

The status code shows where the shop order is in the remanufacturing process. It also controls what you can do with the shop order. You cannot manually change a shop order's status. The system does this automatically in response to actions performed on the shop order. When you enter a new shop order, the system sets its status automatically to either Planned or Released depending on the setting on the Site/Manufacturing page.

The following table summarizes the shop order status codes:

| Status | Description |

| Planned | A low-status shop order, e.g., an order for a part that you have planned but have not yet made the final decision to remanufacture. You cannot reserve material or report operations for an order with this status. |

| Parked | A shop order that has been blocked and cannot/should not be further processed until the cause has been resolved. Depending on the park reason the order can release its reservations, load, supply and demand allocations. Unparking the order will set back the status to the same as before it was parked. |

| Released | A shop order that has been released for production. |

| Reserved | A shop order with at least one reserved material line, but no issued material, or reported operations. |

| Started | A shop order with issued material and/or reported operations. |

| Closed | A shop order that has been completed. No additional quantity can be reported or received unless it is re-opened. |

| Cancelled | A shop order that cannot be further processed. Cannot be re-opened. |

Pegged Direct Supply

Components on a remanufacturing shop order can be directly supplied from parts produced on supply orders if these orders are pegged to the remanufacturing shop order. When a component that is required either directly or as an alternate component on the remanufacturing shop order is received from a pegged supply order, it will be automatically reserved to the remanufacturing shop order. If the received component is required as an alternate component, a replacement of the main component to this alternate component will be automatically performed. A supply order can either be a disassembly shop order or a remanufacturing shop order.

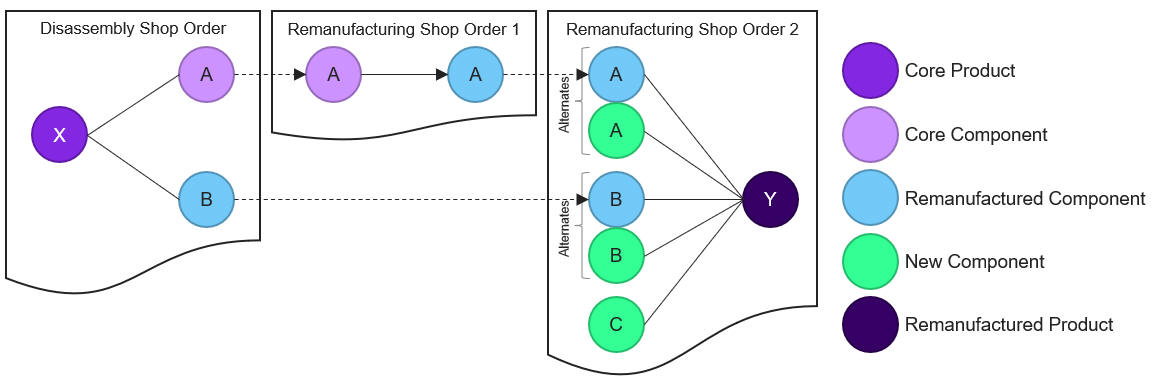

Example:

- The disassembly of the Product X results in Component A and Component B.

- Component B can be directly used as a component in the remanufacturing of the Product Y.

- Component A needs to be remanufactured on its own order before it can be used as a component in the remanufacturing of the Product Y.

- Component C always needs to be replaced with a new component in the remanufacturing of Product Y.

- Remanufactured Component A and Remanufactured Component B have been defined as alternate components to New Component A and New Component B in the remanufacturing structure of the Product Y.

- Remanufacturing Shop Order 1 has the Disassembly Shop Order as a pegged supply order.

- Remanufacturing Shop Order 2 has both the Disassembly Shop Order and Remanufacturing Shop Order 1 as pegged supply orders.

- When Core Component A is received from the Disassembly Shop Order, it is automatically reserved to Remanufacturing Shop Order 1.

- When Remanufactured Component A is received from the Remanufacturing Shop Order 1, it is automatically reserved to Remanufacturing Shop Order 2. This automatically reduces the quantity required of New Component A and replaces it with the reserved quantity of Remanufactured Component A.

- When Remanufactured Component B is received from the Disassembly Shop Order, it is automatically reserved to Remanufacturing Shop Order 2. This automatically reduces the required quantity of New Component B and replaces it with the reserved quantity of Remanufactured Component B.