Configuration Structures

A configuration structure is the definition of possible materials and back office rules used to make up a configurable parent part. Just as in product structures, the configuration structure identifies the components used to manufacture, remanufacture or repair a parent part. It also identifies the by-products and disassembly components produced from the respective process. However, a configuration structure represents an array of structure possibilities depending on specific configuration values. Back office configuration rules (see About Back Office Configuration Rules) attached to the structure elements determine which element should be included or modified to meet the required parent configuration. The configuration structure is a generic definition. Production or repair orders might involve order-specific changes to this list of needed components, but the list of components for the order is initially created based on evaluation of the configuration structure rules of the ordered part's configuration specification.

Configuration structures are used by master scheduling and costing to determine what components are in demand, based on an expected average planning rate of use. They are used by discrete manufacturing to determine the components required to manufacture/remanufacture a part, or the additional material needed to repair one. Configuration structures are also used to help in calculating costs and production lead times. Configure to order manufacturing is dependent on configuration structure definitions.

Configuration structures are divided into three elements: a structure header, a structure alternate and structure line items.

Structure Header

A structure header is where the part, site, revision, and type of configuration structure are identified. Possible configuration structure types are:

| Type | Description |

| Manufacturing | Used when the part is planned or manufactured. It contains the components potentially required to manufacture the part and possible by-products and disassembly components produced in addition to the main product during the manufacturing process. A product structure header of this type is automatically created for inventory parts with Part Type set to Manufactured. |

| Repair | Used when repairing the part. It contains the components potentially required for the repair process, and possible by-products and disassembly components to be received in addition to the main product during the repair process. If the components required are not known in advance, the structure can be left empty and still set to buildable. Note that the repair part is not included in the structure but automatically added as a component on the repair shop order. |

| Prototype | Used when prototyping a part. It contains the components potentially required to manufacture the prototype part and possible by-products and disassembly components produced in addition to the main product. Note that a prototype creates a unique part revision with the Prototype Part Revision Prefix defined on Site/Manufacturing, and always remains in status Tentative. |

| Remanufacturing | Used to remanufacture a part. I.e., restoring it to a like-new condition. It contains the components potentially required to remanufacture the part and possible by-products and disassembly components produced in addition to the main product during the remanufacturing process. A remanufactured product can consist of both new and used components. It is recommended to add the new components in the structure and the corresponding used components as the primary alternate components. A product structure header of this type is automatically created for inventory parts with Part Type set to Remanufactured. |

A part revision may have several structure headers associated with it, one for each of the structure types.

Note: Structure type Purchase is not supported for configuration structures (for technical reasons the structure header can be created, but it is not allowed to enter any components).

Note: A structure with the type Prototype creates a unique part revision with the Prototype Part Revision Prefix defined in the Site/Manufacturing tab.

Structure Alternate

A structure alternate defines the status of a configuration structure and represents a slightly different way of making the same part. The differences might be based on the quantity of parent parts being built, the use of acceptable alternate materials, or some other non-standard condition that indicates a different structure. All structure headers have at least one defined structure alternate, known as the default alternate, which is indicated with an asterisk (*) value in the Alternate field.

The status of the structure alternate indicates how the structure information can be used. The ability to change the component item lines depends upon the status of the alternate structure and the site's Structure/Routing Update setting, defined on the Site/Manufacturing page. Possible statuses are:

| Status | Description |

| Tentative | A structure alternate is created in status Tentative and, normally, this is the default value. This status indicates that the structure alternate is not yet usable, and the structure data will not be used by planning or manufacturing. Components may be changed in this status. |

| Plannable | A structure alternate promoted to status Plannable can be used to calculate cost and planning information, but is still not used for manufacturing. Components may be changed in this status. |

| Buildable | Structure alternates

promoted to status Buildable are completely visible in the system,

and can now be seen and used by manufacturing, as well as for planning

and costing purposes and for generating order components. The Structure/Routing Update setting, defined on the Site/Manufacturing page, determines your ability to modify a component's attributes in this status. If Simplified, most changes are allowed. If Enhanced, only some changes are allowed. If Restricted, most changes are not allowed. |

| Cancelled | The structure alternate has been cancelled and will not be available for use in manufacturing or planning nor used to generate costing information. You can change to this status at any time; however, once done, only the status may be changed. |

| Obsolete | The structure alternate has been obsolete and will not be available for use in manufacturing or planning nor used to generate costing information. You can change to this status at any time; however, once done, only the status may be changed. |

Configuration rules can be associated with a structure alternate. This could be used, for example, to attach conditions such that a different alternate is selected based upon the values for a specific configuration.

Note: If the structure type is Prototype the structure alternate can only have statuses Tentative and Obsolete. The structure alternate is created in status Tentative and can be used by manufacturing. Structure alternates in status Obsolete will not be available for use in manufacturing and cannot be changed to a different status.

Structure Line Items

Configuration rules can be associated with a structure line item and work guideline. For example, conditions could be defined such that different components are selected based upon the values for a specific configuration. Actions could be defined to set an appropriate quantity per assembly based upon the values in the configuration.

Component Usage Factor

Component usage factor is an estimated value which represents the estimated occurrence of the component in created shop orders. Functions like MRP uses this value to plan the components as the configuration and the list of components can be unavailable at the time of planning.

To have a more accurate usage factor, it is possible to calculate the Actual Usage Factor and do the adjustments to the Component Usage Factor which is added in the configuration structure component line. The Calculate Structure Components Actuals dialog is used to perform the calculation and snapshots are created in Structure Component Actuals page, where the calculated Actual Usage Factor is shown.

Component

Components are parts potentially required to manufacture, repair, prototype, ore remanufacture the parent part. Each line item identifies a component and the default quantity per assembly, which is quantity required to manufacture, repair, prototype or remanufacture one unit of the parent part.

- A component can be identified as a Non-Consumed item, which means that although the part appears in the product structure, the demand for that component will not be generated when an order is created for the parent part.

- A structure line item may also be associated with an operation number from the routing for the parent part, indicating that the component will be issued or used during the indicated operation. Functions within Shop Order Operation Reporting will automatically issue material linked to specific operations, and a pick list report can be generated for an operation, showing only material linked to that operation.

- A component can be defined as a Lot/Batch Origin component. The parent part will then inherit the Lot/Batch number from the Lot/Batch Origin component, with a suffix attached. An item can only be named Lot/Batch Origin for Shop orders.

- A component can also be defined as an Expiration Date Origin component. The parent part will then inherit the expiration date from the selected component, or calculate it based on the manufacturing date of the selected component, depending on whether the parent part has a shelf life or not. Several components in a product structure or recipe structure can be selected as Expiration Date Origin components. If this happens, several expiration dates will be calculated and the date closest in the future will be set as the expiration date of the parent part.

By-Product

By-products are parts potentially produced in addition to the main product during manufacturing, repair, prototyping, or remanufacturing. Each line item identifies a by-product part and quantity per unit, which is the default quantity produced relative unit of the parent part.

- A by-product may be associated with an operation number from the routing for the parent part indicating that the by-product will be received when this operation is reported.

Disassembly Component

Disassembly components are parts disassembled from a product during repair, manufacturing, prototyping, or remanufacturing. Each line item identifies a disassembly component part and quantity per unit, which is the quantity disassembled from one unit of the parent part.

- If it is not expected to recover all disassembled components, an expected scrap percentage can be set.

- A disassembly component may be associated with an operation number from the routing for the parent part indicating that the component will be received when this operation is reported.

Direct Supply

For remanufacturing structure alternates, parts that could be disassembled or remanufactured to directly supply the remanufacturing of the main product can be defined. It is possible to rank the priority for each part that is defined as direct supply according to how optimal supply the parts are expected to provide.

Example:

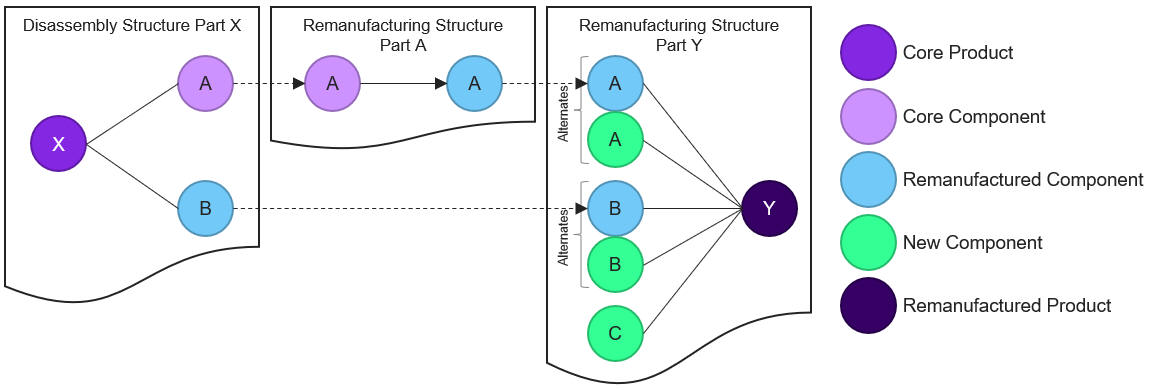

- Product X should be disassembled and Component A should be remanufactured to supply the remanufacturing of Product Y. I.e., the parts received from the disassembly of Product Y and the remanufacturing of Component A should supply the remanufacturing of Product Y.

- Product X with Supply Type set to Disassembly and Component A with Supply Type set to Remanufacturing are added as direct supply to the remanufacturing structure of Product Y.

- When a remanufacturing shop order for Product Y is created, a pegged disassembly shop order for Product X and a pegged remanufacturing shop order for Component A can be created. The part received from the pegged orders will automatically be reserved to the demand order when required. For additional information about pegged supply on remanufacturing shop order, see Remanufacturing Shop Order.