Costing Basic Data

Different costing information is needed to be able to run the costing system properly. Some of the information is defined automatically when setting up the system or creating a new site, but you can also choose to define your own.

Calculation Basic Information

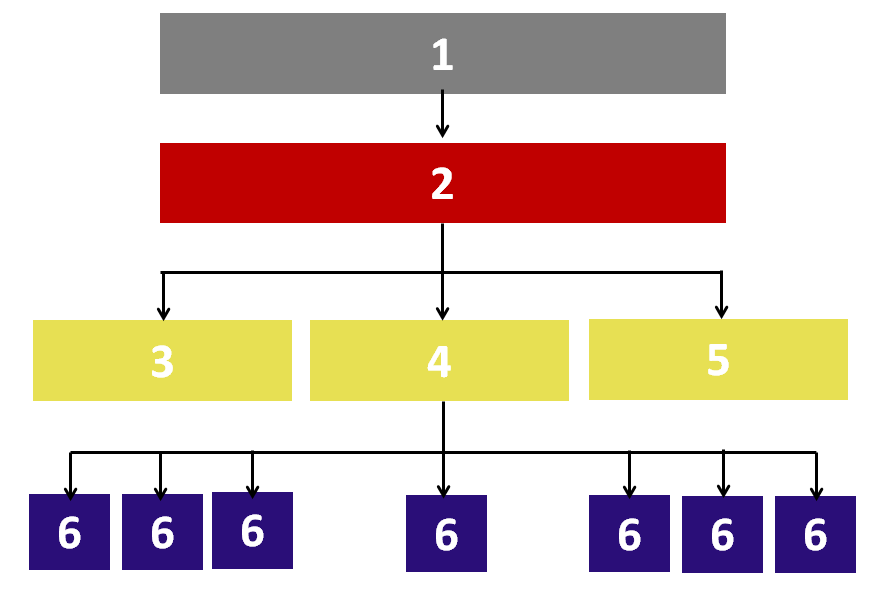

To calculate cost on an inventory part you have to define the cost set you want to use in your calculation. The cost set consists of cost templates, a manufacturing template and a purchasing template. Each cost template has one or several cost buckets assigned and each cost bucket is built up from cost elements. Below are more details about the different types of information you need to define before starting the cost calculation.

Diagram 1 - Calculation Basic Information

1 - Inventory Part (Cost Set)

2 - Template

3 - Bucket 1 - Machine Costs

4 - Bucket 2 - Material Costs

5 - Bucket 3 - Sales Overhead

6 - Cost Element

Cost Set

The cost set is defined per site. Each site gets default cost sets defined automatically when it is created. When working with cost sets, you can redefine a cost set, create a new cost set, and delete any cost set except cost set 1.

Characteristics for Cost Set 1

The following restrictions apply to cost set 1:

- Nothing can be altered or removed, such as costs and templates.

- No calculations can be made.

- All data within the cost set is copied from another cost set.

The above rules and restrictions only apply to cost set 1. All other cost sets and their descriptions may be altered. Cost set 1 holds the standard cost. The standard cost must be calculated in another cost set, since calculations in cost set 1 are not possible. You must copy the desired costs from calculations performed in another cost set via a special copy dialog. Copying cost information into cost set 1 updates the inventory value.

Predefined Cost Sets

When you create a new site, five different cost sets are defined automatically:

| Value | Description |

| 1 | Inventory value |

| 2 | Estimated material cost |

| 3 | Latest purchase price |

| 4 | Average purchase price |

| 5 | Planned purchase cost |

The predefined cost set has a default manufacturing template, a default purchasing template and a default diassembly template.

| Cost Set | Default Manufacturing Cost Template | Default Purchasing Cost Template | Default Disassembly Component Cost Template |

| 1 | M-110 | P-110 | D-110 |

| 2 | M-110 | P-110 | D-110 |

| 3 | M-110 | P-120 | D-110 |

| 4 | M-110 | P-130 | D-110 |

| 5 | M-110 | P-140 | D-110 |

Cost Templates

The use of cost templates enables rapid system set up and ease of use. The templates are used to connect buckets holding costs to the inventory part that will eventually carry the costs.

Predefined Cost Templates

When a site is created, some cost templates are created automatically. These default cost templates have predefined cost buckets assigned to them.

| Cost Template ID | Description | Assigned Cost Bucket | Cost Rollup Control |

| M-110 | Manufacturing Cost Template | 200, 201, 221, 300, 321, 322, 400, 421 | Use Manufacturing Costs |

| P-110 | Estimated Material Cost Template | 110 | Use External Acquired Costs |

| P-120 | Latest Purchase Price Template | 120 | Use External Acquired Costs |

| P-130 | Average Purchase Price Template | 130 | Use External Acquired Costs |

| P-140 | Purchase Cost Template | 140, 160, 170 | Use External Acquired Costs |

| P-150 | Inter-site Material Cost Template | 510 | Use External Acquired Costs |

| D-110 | Disassembly Component Cost Template | 200, 201, 221, 300, 321, 322, 400, 421 | Use Cost Distribution |

The cost templates are connected to the different cost sets created when a new site is created.

The Cost Rollup Control flags controls which types of cost buckets that are considered in the cost calculation (rollup). When Use Cost Distribution is selected it means that the parts will get their costs from Disassembly Cost Calculation.

Note: If you want to capture actual Material Overhead cost in the shop order flow for purchased parts which use the weighted average inventory valuation method or inventory parts with part cost level set to Cost Per Serial, you should use a cost bucket for which the cost element source ID is 500 (Total Cost).

Cost Buckets

The cost bucket contains the costs (cost elements) of any given part registered in the system.

Predefined Cost Buckets

When the system creates a site, some cost buckets are created automatically. These default cost buckets have predefined cost elements assigned to them.

| Cost Bucket ID | Description | Assigned Cost Elements |

| 110 | Estimated material cost | 110 |

| 120 | Latest purchase price | 120 |

| 130 | Average purchase price | 130 |

| 140 | Planned Purchase Price | 140 |

| 160 | Purchase Additional Cost Amount | 160 |

| 170 | Purch Charge on Supplier for Part | 170 |

| 200 | Labor cost | 210, 220 |

| 201 | Labor overhead cost | 210 |

| 221 | Labor overhead cost | 221 |

| 250 | Contract labor cost | 250 |

| 300 | Machine cost | 310, 320 |

| 321 | Machine overhead 1 cost | 321 |

| 322 | Machine overhead 2 cost | 322 |

| 400 | Subcontracting cost | 410, 420 |

| 421 | Subcontracting overhead cost | 421 |

| 510 | Inter-site Material Cost | 510 |

| 150 | DOP Purchased Material Cost | 110. This cost bucket is used by the DOP Actual Cost Calculation. It should not be used for other purposes. |

Cost Elements

A cost element corresponds to a cost generating item, such as a material cost, a work center cost, or a labor cost. Cost elements allow you to choose among a set of predefined cost elements connected to the system. You can also choose to enter your own cost element. A user defined cost element can be one of two kinds: a fixed cost element or a cost element based on a predefined cost element. Creating your own cost elements is the only way to create user defined overhead costs.

You should only use elements for creating overhead costs. Since it is possible to enter an element without an overhead type, elements can be ignored in the shop order process because only system generated elements can be used to capture non overhead costs, such as machine costs, labor costs, material costs, and subcontracting costs.

You can change the factor of any user-defined element except for the below mentioned:

Part-specific overhead trigger elements 501, 502, 141 and 601, and for material overheads using source element 501, for general overheads using source element 502, for delivery overheads using source element 141 and sales overheads using source element 601.

However, note that changing an element factor affects the system's calculation of every part cost using this element. In some cases, there could be thousands of parts connected to a very central element, such as machine cost or material cost.

The fixed cost element is a cost element serving as a fixed markup, while a cost element based on a predefined, system-generated cost element serves as an overhead element carrying a user defined percentage of the cost generated by the underlying cost element. For each cost element you define, you must define the overhead type.

Overhead Types

The overhead type tells the system when to use costs in the accounting system. All overhead types are system generated and correspond to a specific posting type in the system. Depending on the overhead type chosen, the overhead cost is attributed differently and is transferred to WIP (Work in Progress) at a different time, if the final carrier of cost is the basis of a shop order.

| Overhead Type | Corresponding Posting Type |

| Material Overhead | M44 |

| Delivery Overhead | M57 |

| Labor Overhead | M58 |

| Machine Overhead 1 | M45 |

| Machine Overhead 2 | M46 |

| General Overhead | M59 |

| Sales Overhead | M190 |

Predefined Cost Elements

When the system is installed, some predefined cost elements are installed. These system-generated cost elements are already connected to costs and drivers of costs throughout the system.

Note: The cost element 500 is not visible in Cost Elements, but it can be chosen as a source from within the source element's List of Values. This element acts only as the basis for elements with the overhead types Material Overhead or General Overhead If you want to capture actual Material Overhead cost in the shop order flow for purchased parts which use the weighted average inventory valuation method or inventory parts with part cost level set to Cost Per Serial, you should use a cost bucket for which the cost element source ID is 500 (Total Cost).

| Cost Element | Description | Source of Data |

| 110 | Estimated material cost | Cost Set Estimated material cost entered for the cost set in Part Cost/ Part Cost Details or in Part Costs. |

| 120 | Latest purchase price | Latest purchase price on inventory part. |

| 130 | Average purchase price | Average purchase price on inventory part. |

| 140 | Planned Purchase Price | Planned purchase price from the purchasing module. |

| 141 | Purchase Delivery Overhead Trigger | Multiple Delivery Overhead Setup/Supplier, Supplier for Purchase Part, Purchase Part. |

| 160 | Purchase Additional Cost Amount | Additional cost amount from the purchasing module. |

| 170 | Purch Charge on Supplier for Part | Planned charges from supplier for Purchase Part. |

| 210 | Labor setup cost | Labor class costs and Routing Operation |

| 220 | Labor runtime cost | Labor class costs and Routing Operation |

| 221 | Labor overhead cost | Labor class costs and Routing Operation |

| 250 | Contract Labor Cost | Actual labor cost from shop floor reporting |

| 310 | Machine setup cost | Work center costs and Routing Operation |

| 320 | Machine runtime cost | Work center costs and Routing Operation |

| 321 | Machine overhead 1 | Work center costs and Routing Operation |

| 322 | Machine Overhead 2 | Work center costs and Routing Operation |

| 410 | Subcontracting work unit cost | Routing Operation Costs |

| 420 | Subcontracting batch cost | Routing Operation Costs |

| 421 | Subcontracting overhead | Routing Operation Costs |

| 500 | Total cost | Total accumulated cost |

| 501 | Material Overhead Trigger | Part Cost/Part Specific Overheads and Part Specific Overheads |

| 502 | General Overhead Trigger | Part Cost/Part Specific Overheads and Part Specific Overheads |

| 510 | Inter-site Material Cost | Costing/Basic Data/Multi-Site Costing Rules |

| 601 | Sales Overhead Trigger | Part Cost/ Part Specific Overheads and Part Specific Overheads |