Shop Order Requisition

A shop order requisition is a preliminary step to creating a shop order. Also, this can be seen as a proposal on what needs to be manufactured, remanufactured, or disassembled.

A shop order requisition can be created by planning calculations, direct order needs and manual requests. The shop orders you create are used in the shop order module as a basis for material issue, operation reporting, goods receipt, etc.

Once you create a manufacturing type requisition, you can create one or more shop orders from it. Remanufacturing and disassembly requisitions always create one corresponding shop order.

The following table summarizes the types of shop order requisitions:

| Requisition Type | Description |

| Manufacturing | A proposal to manufacture a product. Can be entered manually or be generated from all available sources except from direct supply. |

| Remanufacturing | A proposal to remanufacture a product. I.e., Restoring it to a new condition. Can be entered manually, or generated from master scheduling, MRP, or as a direct supply to another remanufacturing requisition. |

| Disassembly | A proposal to disassemble a product into its components. Can be entered manually or generated as a direct supply to a remanufacturing requisition. |

The following table summarizes the sources of shop order requisitions:

| Requisition Source | Description |

| Master Schedule | A shop order requisition that is system generated from master scheduling during the Level 1 calculation. This calculation considers demand up to the time-limit plan. |

| Project Master Schedule | A shop order requisition that is system generated from project master scheduling. |

| MRP | A shop order requisition that is system generated from material requirements planning (MRP). |

| PMRP | A shop order requisition that is system generated from project material requirements planning (project MRP). |

| Manual | A shop order requisition that is entered manually. |

| Next Level Demand | A shop order requisition that is system generated from a next-level demand calculation. When shop order requisitions are created as a Next Level Demand type, the system determines whether the ownership type of the part is Company Owned. If it is, the shop order requisition will be created. If the ownership type is not Company Owned, a shop order requisition is not created. |

| Reordering Point | A shop order requisition that is system generated from the order proposal process when the stock level falls below the specified re-ordering point. |

| Kanban | A shop order requisition that is system generated from Kanban replenishment. |

| Prod Line Management | A shop order requisition that is system generated for a specific production line using takt time planning from the Production Line Management page. |

| Direct Supply | A shop order requisition that is system generated as a result of the creation of a remanufacturing requisition using a structure alternate with a defined direct supply. |

A shop order requisition can have one of the following statuses:

- Proposal Created - A requisition has been created and exists in the system but has not been converted to a shop order.

- Shop Order Created - One or more shop orders have been created from the shop order requisition.

Pegged Direct Supply

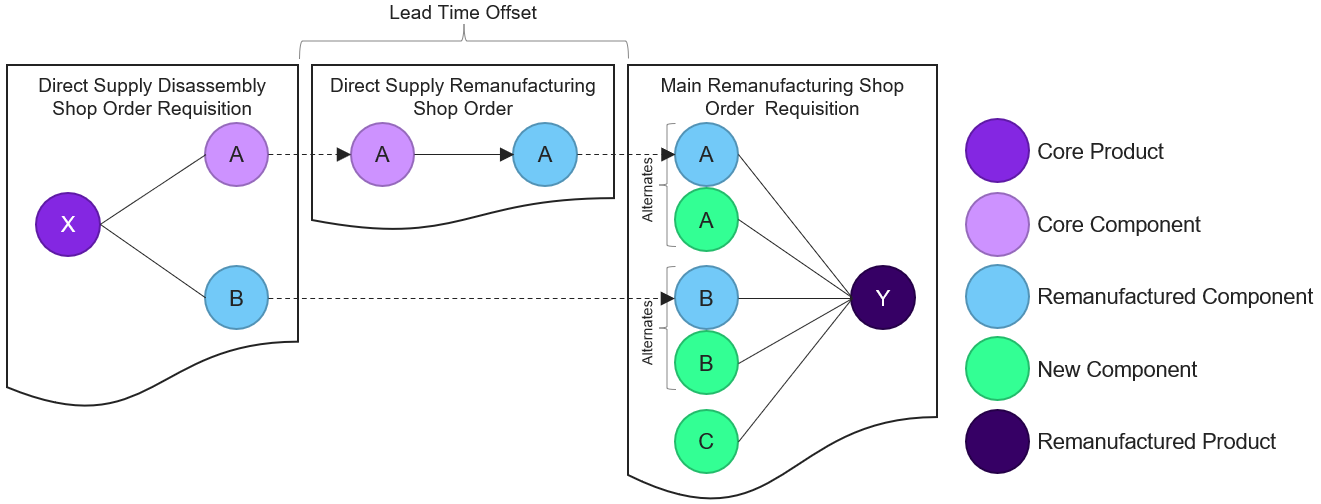

For remanufacturing requisitions, direct supply can be used to plan parts that should be disassembled or remanufactured to supply the remanufacturing of the main product. When the structure alternate used on the remanufacturing requisition has direct supply defined with Supply Qty per Unit > 0, a requisition for this part and structure type is automatically created and pegged to the main remanufacturing requisition. MRP can identify the supply from this requisition required either directly or as an alternate component in the remanufacturing structure and hence, reduce the planned requirement of new components in the remanufacturing structure.

Note that the direct supply planned for a shop order requisition is a preliminary supply. Once the requisition for the main product is converted into a shop order, the requisitions for the direct supply are handled according to the selected Requisition Conversion option. If the direct supply requisitions are deleted, direct supply for the remanufacturing shop order can instead be planned based on the current part availability.

Example:

- Product X is planned to be disassembled and Component A is planned to be remanufactured to supply the remanufacturing of Product Y. I.e., the parts received from the disassembly of Product X and the remanufacturing of Component A should supply the remanufacturing of Product Y.

- Product X with Supply Type set to Disassembly and Component A with Supply Type set to Remanufacturing are added as direct supply to the remanufacturing structure of Product Y with a Supply Qty per Unit > 0.

- A Lead Time Offset is set for Product X to plan its completion a number of workdays before the start of the remanufacturing of Product Y to allow also the remanufacturing of Component A to be completed before the start of the remanufacturing of Product Y.

- When a shop order requisition is created to remanufacture Product Y, pegged direct supply shop order requisitions are automatically created to disassemble Product X and to remanufacture Component A.

- MRP can net the demand of New Component A and New Component B with the supply of the Remanufactured Component A and Remanufactured Component B.