Shop Order Tracked Structure

For multi-level tracked parts, a shop order tracked structure is used to track which parent serial or lot/batch number component parts are assigned to during the manufacturing process. A multi-level tracked part is serial and/or lot/batch tracked and has Multi-Level Tracking enabled on the Part page. Before a parent serial or lot/batch number is received from a shop order, the tracked structure of that serial or lot/batch number must be complete.

Generation of Shop Order Tracked Structure

It is possible to generate shop order tracked structures for multi-level tracked parts that are produced on shop orders both manually and automatically.

The Auto Build Tracked Structure option defined on the Site/Manufacturing page determines whether shop order tracked structures should be generated automatically when parent serial and/or lot/batch numbers are reserved and components are reserved/issued.

- If Auto Build Tracked Structure is enabled, a tracked structure is automatically generated when parent serial and/or lot/batch numbers are reserved, and components are reserved/issued. This implies that the system recommends the parent serial and/or lot/batch number to which the components should be assembled. However, manual adjustments can still be made if necessary.

- If Auto Build Tracked Structure is disabled, no tracked structure is automatically generated when parent serial and/or lot/batch numbers are reserved, and components are reserved/issued. Instead, the user usually assigns the parent serial and/or lot/batch number to the components that are assembled manually. However, it is also possible to initiate an automatic build of the tracked structure if desired.

Automatic Generation of Shop Order Tracked Structure

When shop order tracked structures are generated automatically, the system assigns as much as possible of components to the first parent serial or lot/batch number before continuing to assign anything to the next. The component quantity assigned to each parent is no larger than the quantity per assembly of the component multiplied by the quantity of that specific parent. However, if a component has been replaced with alternate component(s), the main component and the alternate component(s) are considered together during the generation of the tracked structure. In this case no larger quantity than the sum of the quantity per assembly for the main and alternate component(s) multiplied by the quantity of the specific parent is assigned to each parent.

Exception: Components with Exclude from As-Built Structure enabled are never assigned to any parent in the shop order tracked structure.

Below, example 1 demonstrates how the automatic generation of the shop order tracked structure is done when no components have been replaced with alternate component(s), while example 2 demonstrates how the automatic generation of the shop order tracked structure is done when a component has been replaced with alternate component(s).

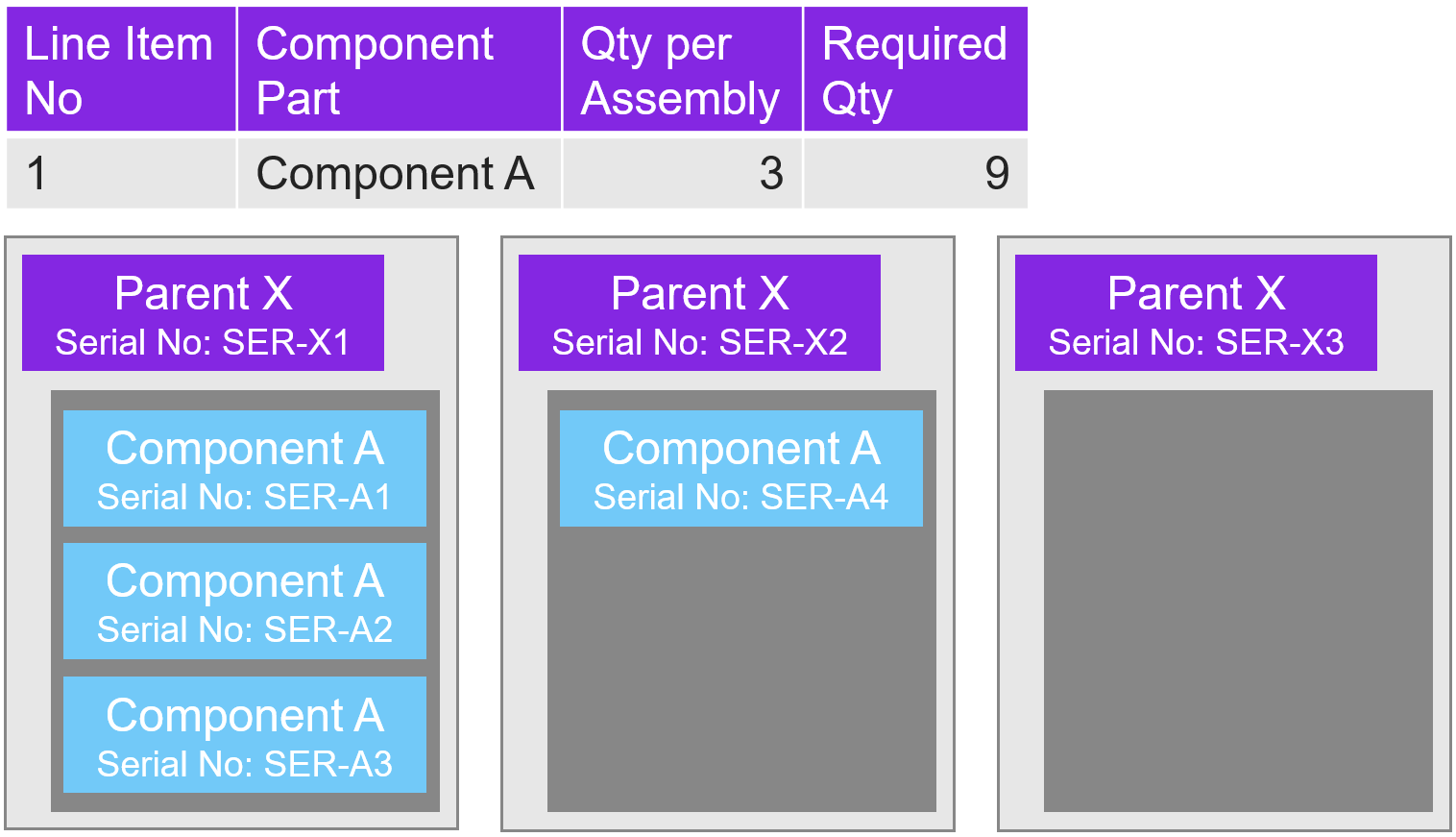

Example 1:

Three units of serial tracked parent part X are produced on a manufacturing shop order. The shop order has a material line with serial tracked component A and quantity per assembly set to 3. When three serial numbers have been reserved for parent part X and four units of component A have been reserved/issued, the automatically generated shop order tracked structure will be built as displayed in the picture below. Note that the system first assigns three units of component A to the first parent, that is equal to the quantity per assembly of component A multiplied by the quantity of the first parent (3 * 1 = 3), before continuing to assign anything to the next.

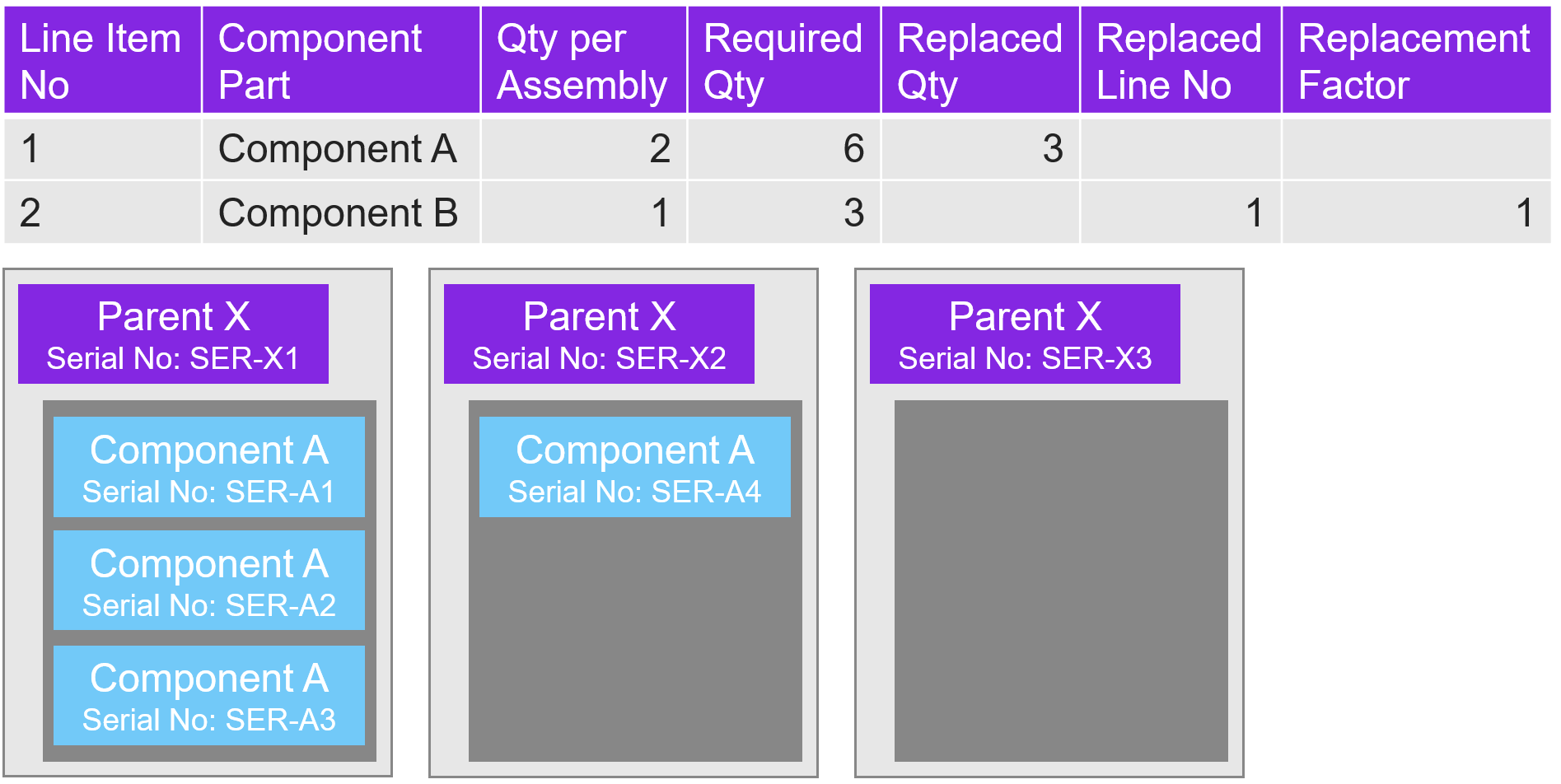

Example 2:

Three units of serial tracked parent part X are produced on a manufacturing shop order. The shop order has two material lines. The first material line is for serial tracked component A and has quantity per assembly set to 2. The second material line is for serial tracked component B and has quantity per assembly set to 1. The second material line was created when three units of component A on the first material line were replaced with three units of alternate component B. When three serial numbers for parent part X have been reserved and four units of component A have been reserved/issued, the automatically generated shop order tracked structure will be built as displayed in the picture below. Note that the system first assigns three units of component A to the first parent, that is equal to the sum of the quantity per assembly for the main component A and the alternate component B multiplied by the quantity of the first parent ((2 + 1) * 1 = 3), before continuing to assign anything to the next.

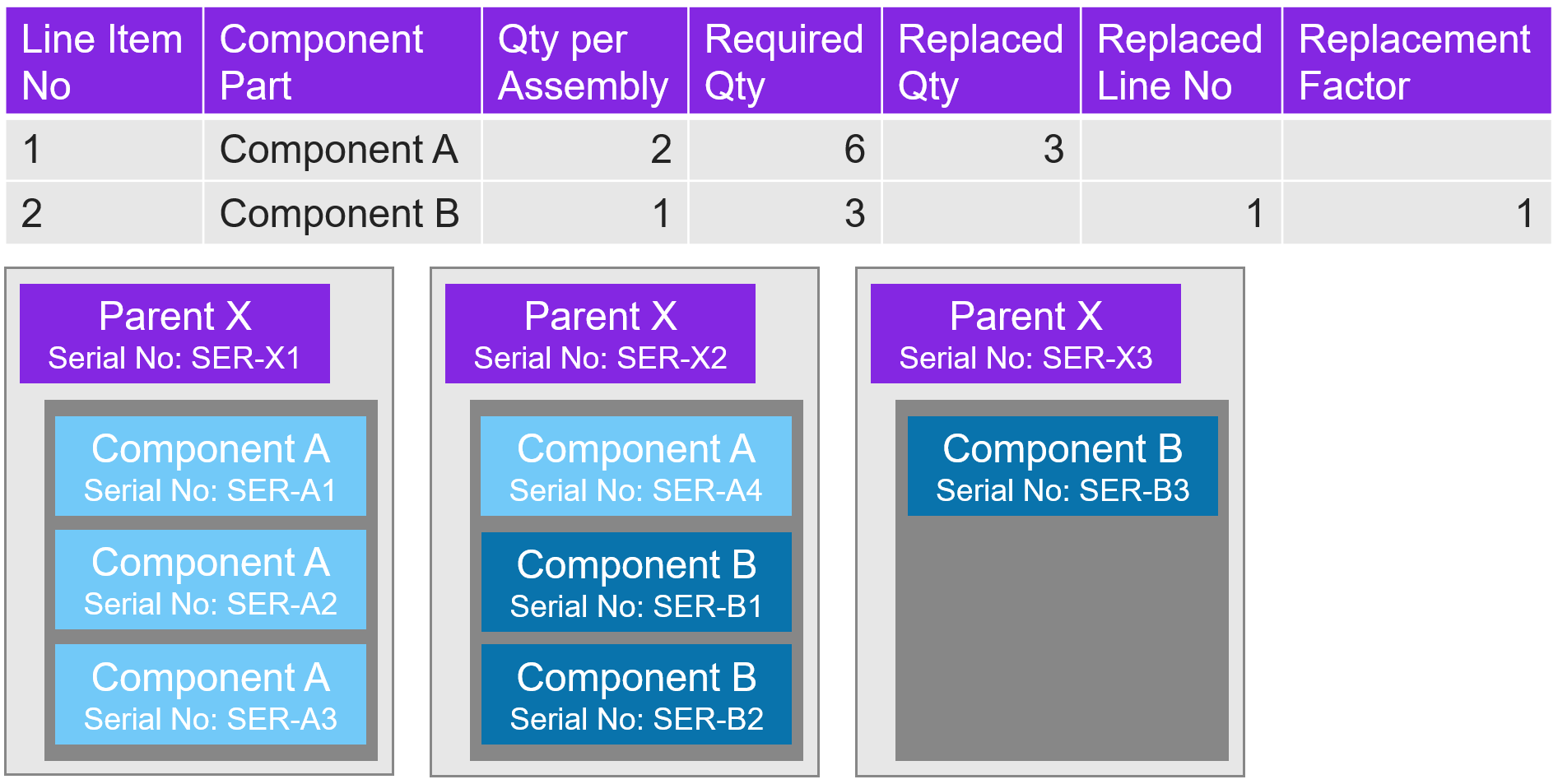

When three units of component B have been reserved/issued, the automatically generated shop order tracked structure will be built as displayed in the picture below.

Validation of Tracked Structure Complete

The tracked structure of a specific serial or lot/batch number on a shop order is validated as complete if enough quantity of all the components has been assigned to it. The component quantity assigned to the parent must be equal to the quantity per assembly of the component multiplied by the quantity of the specific parent. However, if a component has been replaced with alternate component(s), the sum of the component and alternate component(s) quantities assigned to the parent must be equal to the sum of the quantity per assembly of the main and alternate component(s) multiplied with the quantity of the specific parent.

Exceptions: Components with Exclude from As-Built Structure enabled are excluded from the validation. For components with the reserve/issue method set to Manual, it is enough if just some quantity has been issued.

Below, example 3 demonstrates how the tracked structure is validated when no components have been replaced with alternate component(s), while example 4 demonstrates how the structure is validated when a component has been replaced with alternate component(s).

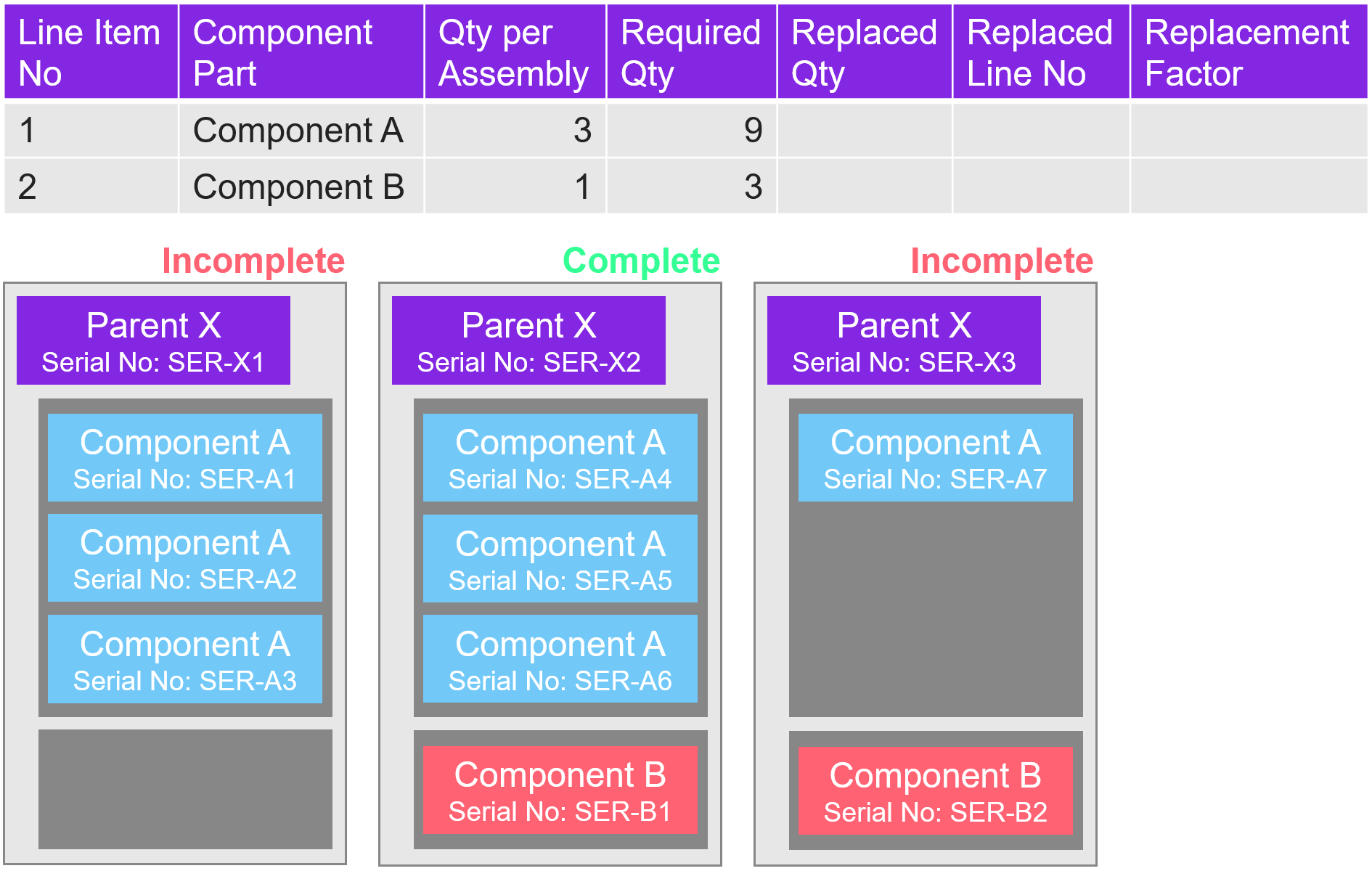

Example 3:

Three units of serial tracked parent part X are produced on a manufacturing shop order. The shop order has two material lines. The first material line is for serial tracked component A and has quantity per assembly set to 3. The second material line is for serial tracked component B and has quantity per assembly set to 1. When the tracked structure is built as displayed in the picture below, only the second parent is validated as complete. Note that the quantity of component A, three units, that is assigned to the second parent is equal to the quantity per assembly of component A multiplied by the quantity of the second parent (3 * 1 = 3). The quantity of component B, one unit, that is assigned to the second parent is equal to the quantity per assembly of component B multiplied by the quantity of the second parent (1 * 1 = 1).

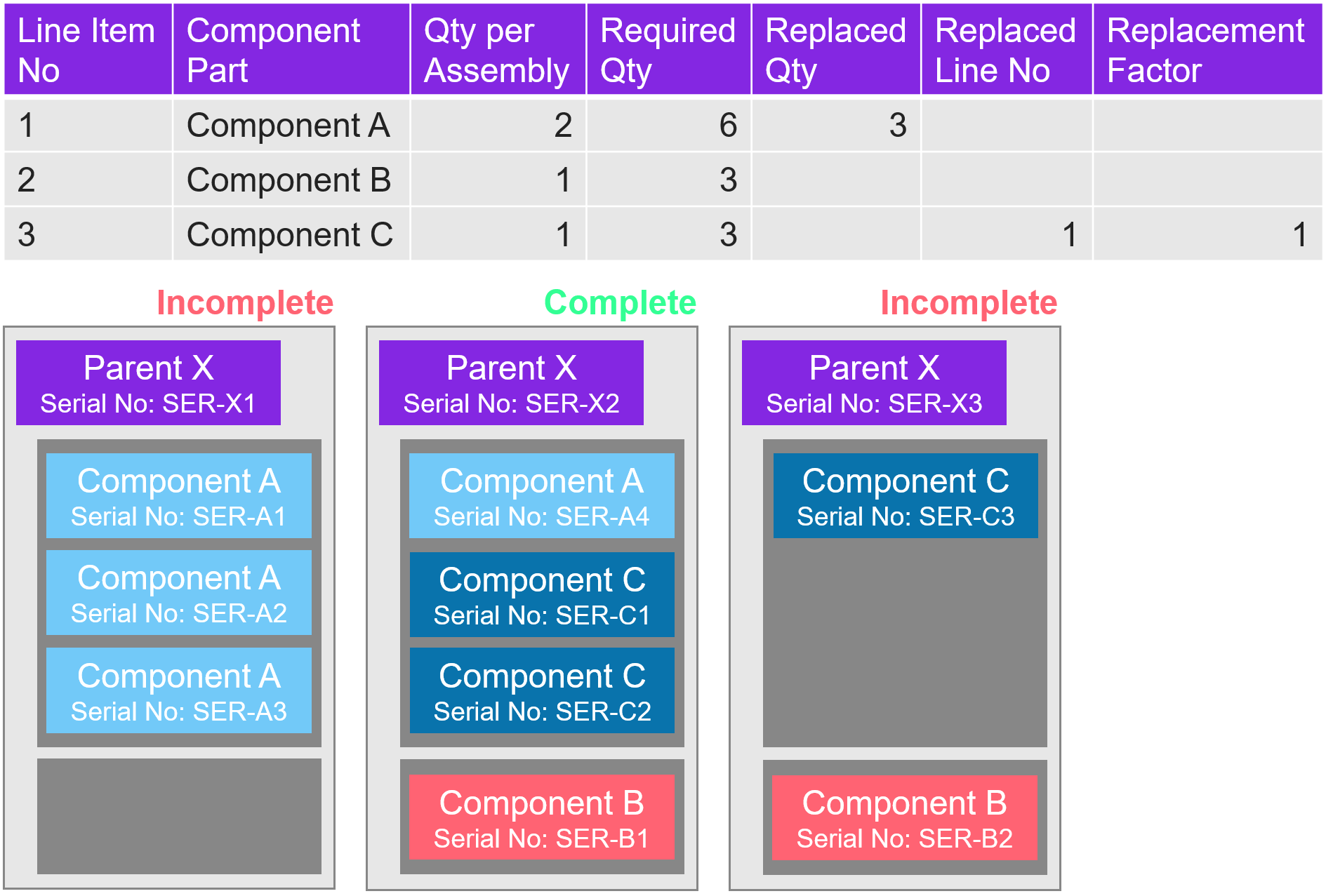

Example 4:

Three units of serial tracked parent part X are produced on a manufacturing shop order. The shop order has three material lines. The first material line is for component A and has quantity per assembly set to 2. The second material line is for component B and has quantity per assembly set to 1. The third material line is for component C and has quantity per assembly set to 1. The third material line was created when three units of component A on the first material line were replaced with three units of alternate component C. When the tracked structure is built as displayed in the picture below, only the second parent is validated as complete. Note that the sum of the quantity of main component A and alternate component C, one plus two units, that is assigned to the second parent is equal to the sum of the quantity per assembly for main component A and alternate component C multiplied by the quantity of the second parent ((2 + 1) * 1) = 1. The quantity of component B, one unit, that is assigned to the second parent is equal to the quantity per assembly of component B multiplied by the quantity of the second parent (1 * 1) = 1.