About Engineering Part Revisions

Engineering part revision is the cornerstone of the PDM Configuration module. For each engineering part, you may have one or several revisions. Each revision has a set of properties which must be configured according to your requirements. The general properties are given below:

- Document references include full revision control for parts and documents.

- Standard documentation requirements can either be assigned to a part class or tailored for each part revision.

- Approval routings which include electronic signatures.

- Part development journal keeps track of all status modifications — provides the what, when, who, and why for each change

- The pre-release checking of a part can be customized.

- Document survey which shows the documents connected to parts and tags. When the part revision is released the document survey will be in the locked status. It is not possible to remove documents from the locked survey. You can add new documents when the survey is in the locked status and these documents can also be removed.

- Spare part list. Any engineering part revision can have a spare part list.

- A "consist of" functionality describing child parts on the next level below .

- A "where used" functionality describing all the parents where the selected part is used.

- A multilevel functionality listing all child parts for all levels.

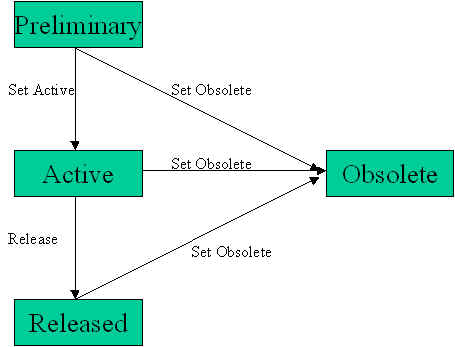

When creating a new engineering part revision, the part gets a default status called preliminary. When you are finished developing the part, the part is set to released status. An engineering part which is not needed should be set to obsolete. This means that the part cannot be used any further. Each obsolete revision with all its data is available for tracing and analyzing as long as the revision is not deleted.

An engineering part revision has a lifecycle described by a state machine. The figure below describes the possible status values: