Serial Lifecycle Group

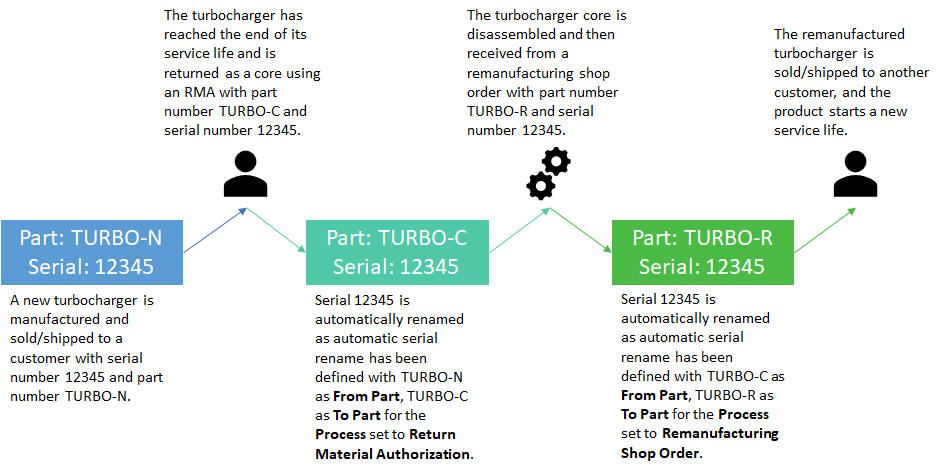

During its lifecycle, a serial-tracked product may need to change its part number as its form, fit, and function evolve. This situation typically arises in circular business processes such as refurbishment and remanufacturing.

The serial lifecycle group is used to group serial tracked part numbers, where a serial number represents the same individual product but at different lifecycle stages. A serial number can only be active for one part number within a serial lifecycle group at any given time. A part is active except when its Current Position is set to Unlocated and its Operational Status is set to Renamed. This means:

- A part cannot be connected to a serial lifecycle group if it has an active serial number that also exists for another part within the serial lifecycle group.

- A serial number cannot be reserved or created if it already exists as an active serial for another part within the same serial lifecycle group.

Automatic Serial Rename

The system can be configured to allow a serial number to be reserved or created for a part even if it already exists for another part within the same serial lifecycle group, by using automatic serial rename. This will automatically change the Current Position to Unlocated and the Operational Status to Renamed for the existing part serial and create a traceability between the previous and new part serial. The automatic rename is defined by:

- From Part: The part number that the serial can be renamed from.

- To Part: The part number that the serial can be renamed to.

-

Process: The process for which the automatic serial rename should occur for the from/to part

combination. The following processes are supported:

- Purchase Order Receipt: A purchase order that is either reported as arrived (transaction code: ARRIVAL), or split into serials (transaction code: SERIAL-IN).

- Return Material Authorization: An order less return material authorization (RMA) that is either scrapped (transaction code: OERET-SPNO), reported as arrived (transaction code: OERET-NO), or split into serials (transaction code: SERIAL-IN).

- Remanufacturing Shop Order: A remanufacturing shop order that is received to stock.

- Shop Order Disassembly Component: A shop order disassembly component that is received to stock.

Example

Prerequisites

An automatic serial rename will only occur if the below conditions are met:

- The Current Position of the existing part serial must be Returned to

Supplier, Contained, Issued or Unlocated.

- If the Current Position is Contained, the Current Position Top Part must be Returned to Supplier, Issued or Unlocated. If it is Unlocated, the top parent Operational Status must not be Scrapped.

- If the Current Position is Issued, the issue must be to a customer order, project deliverables or without order connection.

- If the Current Position is Unlocated, the Operational Status must be Disassembled.

- The serial number must not be defined as a VIM, Equipment, Tool Equipment or a Plant Design object.

System Effects

As a result of serial lifecycle rename, below system effects can be expected:

- The Current Position of the serial number for the existing part on the Part Serial page is set to Unlocated and the Current Position to Renamed.

- The rename is logged on the Part Serial Rename History page with the Rename Reason set to Serial Lifecycle Rename.

- Document and technical class characteristics attached to the part serial of the renamed from part are moved to the part serial of the renamed to part on the receipt line.

Note that the serial structure and as-built structure of the existing part serial, from which the rename is done, are not transferred or copied to the new part serial during serial lifecycle renaming