Smart Manufacturing Planning Board

Smart Manufacturing Planning Board (SMPB) is the Interactive scheduling tool designed to plan and schedule with

MSO.

Data loading into these pages can be predefined as Smart Manufacturing Planning Board filters.

- Activity Description for Smart Manufacturing

Planning Board Filter

Two Views in SMPB

SMPB is designed as a two page solution based on different viewing perspectives.

1. Smart Manufacturing Planning Board - Resources

This page loads Resources into the Gannt chart and shows operations assigned for each

resource. (i.e. Machines, People and Tool Instances). This can be used to view and adjust allocations, as well as to

change the Work Center or Labor Class assignments as a standalone tool that is designed to simplify the Work of a

Manufacturing Planner.

2. Smart Manufacturing Planning Board - Operations

This page loads Operations into the Gannt chart and shows order structures scheduled over the

Time. (i.e. Muti-level Shop order structures, with DOP, Project and Batch Balance information). This page has DOP

header, Projects, Batch Balance columns in the Gannt thus users can view and adjust allocations, plan for multi-level

Shop Orders based on Order structure-related schedules,

Both of these pages will be enabled automatically for all MSO dataset enabled sites. The

Scheduling status of the MSO scheduling service is shown in SMPB pages with latest schedule accepted quality and the

accepted time.

In the Gantt view, the user can make Shop Order related changes, like Shop Order Operation Split, change preferred

resource, selective optimization, finite operation block creation, etc.

On Finite Scheduling Basic Data page, Smart Manufacturing Planning Board Tab,

Allow Re-Assignment when Drag and Drop group, the User can control the re-assignment

requirement of other activities of the Same Shop Order Operation when dragging and dropping a specific activity of a

Shop Order Operation.

- If Work Center Resource toggle is enabled, the Scheduling service will freely re-assign the

Shop Order Operations to the Most suitable Machine resource (Work Center Resource) when the User performs Drag and

Drop actions for Labor or Tool related activities of the Same Shop Order Operation.

- If Person toggle is enabled, the Scheduling service will freely re-assign the Shop Order

Operations to the most suitable Person (Labor Class Person resource) when User performs Drag and Drop actions for

Machine or Tool related activities of the Same Shop Order Operation.

- If Tool toggle is enabled, the Scheduling service will freely re-assign the Shop Order

Operations to the most suitable Tool Instance resource when User performs Drag and Drop actions for Machine or Tool

related activities of the Same Shop Order Operation.

Drag and Drop Scheduling

In SMPB, the User can adjust, drag and drop, or manually fix any operation based on any business requirement.

To do this action User needs to follow these steps

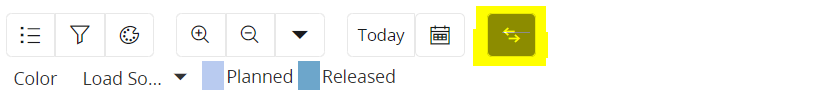

- Enable the Insert Mode to adjust shop order operations.

- Drag and drop required operations to the required time position in the timeline. ((Optional) Resource

re-assignment will also occur if the user drags them to another resource)

- All Manually made changes will be shown in the Unsaved Fixed Orders list in SMPB. Users can undo or unsave

selected changes from this list.

- Upon drag and drop action, Fixed operation will be shown in dark blue colour and affected Operations will

be shown in Light Green colour.

- If there is any overload situation due to manual drag and drop action, Resource icon colour will be

represented in Red colour. A Green color icon will be shown when the Resource capacity is Balanced.

- (Optional) Resource re-assignment can be controlled further by using Change Drag Drop Setting Enable/Disable

command given in the Gannt header. When this is enabled User input dialog will be prompted upon the completion of

drag and drop action.

- After making required adjustments, all manually made changes can be applied to the finite schedule upon the

execution of the Finite schedule (In Manual MSO) or Save (In Automatic MSO)

actions given in headers section.

Misc. information

- Multiple users can access these pages simultaneously, and any unsaved fixed order changes made by each user

will be applied and updated in the finite schedule on the Site on-demand basis.

- Resource type is represented by icon on Resource column. Colour of this icon changes based on the Resource

capacity.

- Green - Underloaded/Balanced

- Red - Overloaded

- Gray - Not Loaded

- Orange - Loaded But No capacity details

- In Operations Gannt order schedulable period also can be shown in the SMPB Operations view Gannt. i.e. Period

in-between EPST and Need date (This can be enabled/disabled from Gannt legend)