Configure MSO Advanced Parameters

Explanation

Please note that any modifications to these parameters should be carried out exclusively by authorized personnel, specifically MSO and PSO Subject Matter Experts (SMEs), as unauthorized changes may significantly impact scheduling logic and system performance.

- MSO Model tab contains system-level parameters relevant to MSO-PSO (Manufacturing Scheduling Optimization and Planning Scheduling Optimization).

- PSO Profile tab includes tenant-specific parameters related to the MSO profile used in the PSO Finite Scheduling Service.

The standard MSO advanced parameter template (named 0-Standard) serves as the default template applied across

all MSO datasets (Finite Scheduling Basic Data for Sites).

Authorized users can create new MSO advanced parameter templates or modify existing ones to address specific finite

scheduling requirements. All active templates are editable and can be linked to the appropriate finite scheduling

basic data for each site by using the designated column in the Advanced tab of the

Finite Scheduling Basic Data page. The template specified is also used by default in MSO

simulation scenarios.

Each parameter's default value has been tested and is recommended for standard finite scheduling use cases. Therefore, adjustments must be approached with caution, thoroughly validated, and properly documented to maintain system integrity and operational reliability.

This configuration page contains default parameter values that have been rigorously tested and are recommended for standard users to ensure optimal performance and consistent scheduling behavior within the MSO system.

SLA (Service-Level-Agreement in PSO) related list of parameters can be explained individually as below. Advanced users can configure each parameter value to control the different KPIs and generate an expected scheduling outcome.

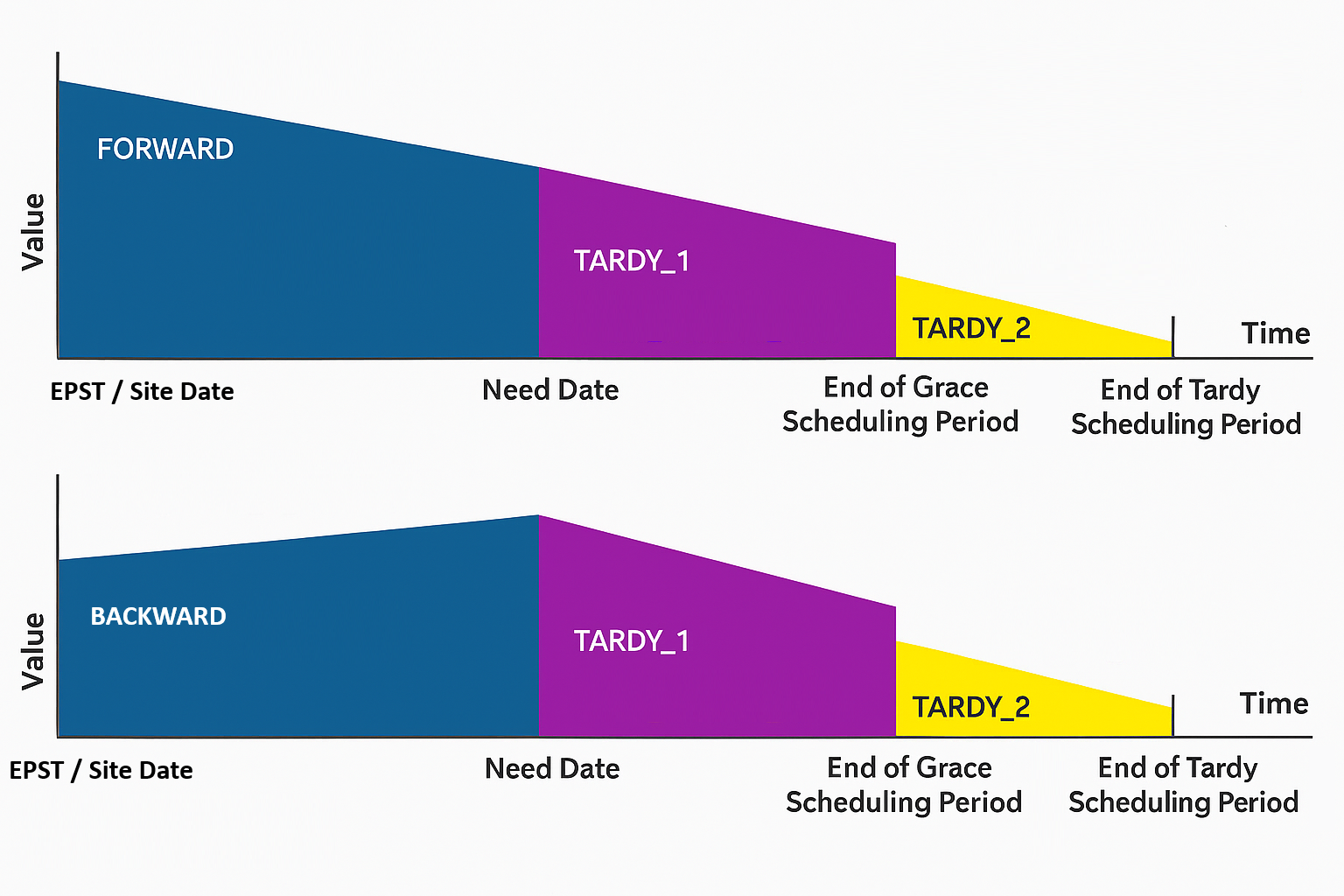

Figure 1 - Forward and Backward Scheduling related MSO-PSO SLA model current value variation over time

In order to optimize the scheduling result in an early or on-time scheduling period, an advanced user can modify SLA parameters given in the Table 1 below and reach different schedule results by controlling the potential to schedule closer to the Need date or Closer to the Earliest possible Start Time. All these Parameters in Table 1 will configure the scheduling result for F_Px_SLA and B_Px_SLA. Value 'x' represents the priority category of the shop order. By modifying these values, the user can optimize on different aspects like the number of early orders, average earliness, etc..

| Standard Shop Order Operation Early/On-time Scheduling related SLA

Parameters (Applies to all except machine setup time and tool setup time related activity SLAs) |

|||||||

| PSO SLA Parameters | Shop Order Scheduling Direction | SLA_type | Shop Order Priority Category related MSO Priority Score | Relative MSO Advanced Parameter | |||

| # | start_proportion | end_proportion | activity_ageing_factor | curve_shape | |||

| 1 | Forward Scheduling | F_P0_SLA | 0 | START_PROP_F-P0-SLA | END_PROP_F-P0-SLA | AGEING_FACTOR_F-P0-SLA | CURVE_SHAPE_F-P0-SLA |

| 2 | Forward Scheduling | F_P1_SLA | 1 | START_PROP_F-P1-SLA | END_PROP_F-P1-SLA | AGEING_FACTOR_F-P1-SLA | CURVE_SHAPE_F-P1-SLA |

| 3 | Forward Scheduling | F_P2_SLA | 2 | START_PROP_F-P2-SLA | END_PROP_F-P2-SLA | AGEING_FACTOR_F-P2-SLA | CURVE_SHAPE_F-P2-SLA |

| 4 | Forward Scheduling | F_P3_SLA | 3 | START_PROP_F-P3-SLA | END_PROP_F-P3-SLA | AGEING_FACTOR_F-P3-SLA | CURVE_SHAPE_F-P3-SLA |

| 5 | Forward Scheduling | F_P4_SLA | 4 | START_PROP_F-P4-SLA | END_PROP_F-P4-SLA | AGEING_FACTOR_F-P4-SLA | CURVE_SHAPE_F-P4-SLA |

| 6 | Forward Scheduling | F_P5_SLA | 5 | START_PROP_F-P5-SLA | END_PROP_F-P5-SLA | AGEING_FACTOR_F-P5-SLA | CURVE_SHAPE_F-P5-SLA |

| 7 | Forward Scheduling | F_P6_SLA | 6 | START_PROP_F-P6-SLA | END_PROP_F-P6-SLA | AGEING_FACTOR_F-P6-SLA | CURVE_SHAPE_F-P6-SLA |

| 8 | Forward Scheduling | F_P7_SLA | 7 | START_PROP_F-P7-SLA | END_PROP_F-P7-SLA | AGEING_FACTOR_F-P7-SLA | CURVE_SHAPE_F-P7-SLA |

| 9 | Forward Scheduling | F_P8_SLA | 8 | START_PROP_F-P8-SLA | END_PROP_F-P8-SLA | AGEING_FACTOR_F-P8-SLA | CURVE_SHAPE_F-P8-SLA |

| 10 | Forward Scheduling | F_P9_SLA | 9 | START_PROP_F-P9-SLA | END_PROP_F-P9-SLA | AGEING_FACTOR_F-P9-SLA | CURVE_SHAPE_F-P9-SLA |

| 11 | Forward Scheduling | F_P10_SLA | 10 | START_PROP_F-P10-SLA | END_PROP_F-P10-SLA | AGEING_FACTOR_F-P10-SLA | CURVE_SHAPE_F-P10-SLA |

| 12 | Backward Scheduling | B_P0_SLA | 0 | START_PROP_B-P0-SLA | END_PROP_B-P0-SLA | AGEING_FACTOR_B-P0-SLA | CURVE_SHAPE_B-P0-SLA |

| 13 | Backward Scheduling | B_P1_SLA | 1 | START_PROP_B-P1-SLA | END_PROP_B-P1-SLA | AGEING_FACTOR_B-P1-SLA | CURVE_SHAPE_B-P1-SLA |

| 14 | Backward Scheduling | B_P2_SLA | 2 | START_PROP_B-P2-SLA | END_PROP_B-P2-SLA | AGEING_FACTOR_B-P2-SLA | CURVE_SHAPE_B-P2-SLA |

| 15 | Backward Scheduling | B_P3_SLA | 3 | START_PROP_B-P3-SLA | END_PROP_B-P3-SLA | AGEING_FACTOR_B-P3-SLA | CURVE_SHAPE_B-P3-SLA |

| 16 | Backward Scheduling | B_P4_SLA | 4 | START_PROP_B-P4-SLA | END_PROP_B-P4-SLA | AGEING_FACTOR_B-P4-SLA | CURVE_SHAPE_B-P4-SLA |

| 17 | Backward Scheduling | B_P5_SLA | 5 | START_PROP_B-P5-SLA | END_PROP_B-P5-SLA | AGEING_FACTOR_B-P5-SLA | CURVE_SHAPE_B-P5-SLA |

| 18 | Backward Scheduling | B_P6_SLA | 6 | START_PROP_B-P6-SLA | END_PROP_B-P6-SLA | AGEING_FACTOR_B-P6-SLA | CURVE_SHAPE_B-P6-SLA |

| 19 | Backward Scheduling | B_P7_SLA | 7 | START_PROP_B-P7-SLA | END_PROP_B-P7-SLA | AGEING_FACTOR_B-P7-SLA | CURVE_SHAPE_B-P7-SLA |

| 20 | Backward Scheduling | B_P8_SLA | 8 | START_PROP_B-P8-SLA | END_PROP_B-P8-SLA | AGEING_FACTOR_B-P8-SLA | CURVE_SHAPE_B-P8-SLA |

| 21 | Backward Scheduling | B_P9_SLA | 9 | START_PROP_B-P9-SLA | END_PROP_B-P9-SLA | AGEING_FACTOR_B-P9-SLA | CURVE_SHAPE_B-P9-SLA |

| 22 | Backward Scheduling | B_P10_SLA | 10 | START_PROP_B-P10-SLA | END_PROP_B-P10-SLA | AGEING_FACTOR_B-P10-SLA | CURVE_SHAPE_B-P10-SLA |

Table 1- MSO SLAs related parameters - Early/On time

As shown in Table 2 below, MSO refers to specific SLAs for setup times of Machines and Tools to support scenarios where the same resource transitions from a 'Setup' to 'Run' activity within the same Activity Group via Order_One_Way condition. These SLAs are designed to optimize scheduling by minimizing unnecessary gaps between setup and run times when scheduling on different SLAs. However, for labor setup activities, MSO does not apply these special SLAs, as setup and run operations can be performed by different resources. Therefore, MSO does not generate any 'Order_One_Way' conditions for labor setup-to-run relationships.

| Special Scenario for shop Order setup time related Early/On-time Scheduling parameters (Applies for machine setup time and tool setup time related activity SLAs) | |||||||

| PSO SLA Parameters | Shop Order Scheduling Direction | SLA_type | Shop Order Priority Category related MSO Priority Score | Relative MSO Advanced Parameter | |||

| # | start_proportion | end_proportion | activity_ageing_factor | curve_shape | |||

| 23 | Forward Scheduling | F_SETUP_SLA | All | START_PROP_F_SETUP_SLA | END_PROP_F_SETUP-SLA | CURVE_SHAPE_F_SETUP-SLA | AGEING_FACTOR_F_SETUP-SLA |

| 24 | Backward Scheduling | B_SETUP_SLA | All | START_PROP_B_SETUP_SLA | END_PROP_B_SETUP-SLA | CURVE_SHAPE_B_SETUP-SLA | AGEING_FACTOR_B_SETUP-SLA |

Table 2- MSO SLAs related parameters - Setup time of Machines and Tools

To optimize scheduling outcomes for shop orders that are delayed or tardy due to capacity constraints, availability issues, or other unavoidable circumstances, MSO utilizes the SLA types listed in Table 3 below. By configuring these values, advanced users can fine-tune scheduling performance based on metrics such as the number of tardy orders and average tardiness. The impact of the grace scheduling period can be adjusted by applying different SLA curve shapes, in accordance with PSO SLA design principles and supporting mathematical analysis.

| Scheduling within the Grace Period after passing the Need date parameters | |||||||

| PSO SLA Parameters | Shop Order Scheduling Direction | SLA_type | Shop Order Priority Category related MSO Priority Score | Relative MSO Advanced Parameter | |||

| # | start_proportion | end_proportion | activity_ageing_factor | curve_shape | |||

| 25 | Any Direction | P0_TARDY1_SLA | 0 | START_PROP_P0_TARDY1_SLA | END_PROP_P0-TARDY1-SLA | CURVE_SHAPE_P0-TARDY1-SLA | AGEING_FACTOR_P0-TARDY1-SLA |

| 26 | Any Direction | P1_TARDY1_SLA | 1 | START_PROP_P1_TARDY1_SLA | END_PROP_P1-TARDY1-SLA | CURVE_SHAPE_P1-TARDY1-SLA | AGEING_FACTOR_P1-TARDY1-SLA |

| 27 | Any Direction | P2_TARDY1_SLA | 2 | START_PROP_P2_TARDY1_SLA | END_PROP_P2-TARDY1-SLA | CURVE_SHAPE_P2-TARDY1-SLA | AGEING_FACTOR_P2-TARDY1-SLA |

| 28 | Any Direction | P3_TARDY1_SLA | 3 | START_PROP_P3_TARDY1_SLA | END_PROP_P3-TARDY1-SLA | CURVE_SHAPE_P3-TARDY1-SLA | AGEING_FACTOR_P3-TARDY1-SLA |

| 29 | Any Direction | P4_TARDY1_SLA | 4 | START_PROP_P4_TARDY1_SLA | END_PROP_P4-TARDY1-SLA | CURVE_SHAPE_P4-TARDY1-SLA | AGEING_FACTOR_P4-TARDY1-SLA |

| 30 | Any Direction | P5_TARDY1_SLA | 5 | START_PROP_P5_TARDY1_SLA | END_PROP_P5-TARDY1-SLA | CURVE_SHAPE_P5-TARDY1-SLA | AGEING_FACTOR_P5-TARDY1-SLA |

| 31 | Any Direction | P6_TARDY1_SLA | 6 | START_PROP_P6_TARDY1_SLA | END_PROP_P6-TARDY1-SLA | CURVE_SHAPE_P6-TARDY1-SLA | AGEING_FACTOR_P6-TARDY1-SLA |

| 32 | Any Direction | P7_TARDY1_SLA | 7 | START_PROP_P7_TARDY1_SLA | END_PROP_P7-TARDY1-SLA | CURVE_SHAPE_P7-TARDY1-SLA | AGEING_FACTOR_P7-TARDY1-SLA |

| 33 | Any Direction | P8_TARDY1_SLA | 8 | START_PROP_P8_TARDY1_SLA | END_PROP_P8-TARDY1-SLA | CURVE_SHAPE_P8-TARDY1-SLA | AGEING_FACTOR_P8-TARDY1-SLA |

| 34 | Any Direction | P9_TARDY1_SLA | 9 | START_PROP_P9_TARDY1_SLA | END_PROP_P9-TARDY1-SLA | CURVE_SHAPE_P9-TARDY1-SLA | AGEING_FACTOR_P9-TARDY1-SLA |

| 35 | Any Direction | P10_TARDY1_SLA | 10 | START_PROP_P10_TARDY1_SLA | END_PROP_P10-TARDY1-SLA | CURVE_SHAPE_P10-TARDY1-SLA | AGEING_FACTOR_P10-TARDY1-SLA |

| Scheduling after Grace Period within Tardy Scheduling Window | |||||||

| PSO SLA Parameters | Shop Order Scheduling Direction | SLA_type | Shop Order Priority Category related MSO Priority Score | Relative MSO Advanced Parameters | |||

| # | start_proportion | end_proportion | activity_ageing_factor | curve_shape | |||

| 36 | Any Direction | P0_TARDY2_SLA | 0 | START_PROP_P0_TARDY2_SLA | END_PROP_P0-TARDY2-SLA | CURVE_SHAPE_P0-TARDY2-SLA | AGEING_FACTOR_P0-TARDY2-SLA |

| 37 | Any Direction | P1_TARDY2_SLA | 1 | START_PROP_P1_TARDY2_SLA | END_PROP_P1-TARDY2-SLA | CURVE_SHAPE_P1-TARDY2-SLA | AGEING_FACTOR_P1-TARDY2-SLA |

| 38 | Any Direction | P2_TARDY2_SLA | 2 | START_PROP_P2_TARDY2_SLA | END_PROP_P2-TARDY2-SLA | CURVE_SHAPE_P2-TARDY2-SLA | AGEING_FACTOR_P2-TARDY2-SLA |

| 39 | Any Direction | P3_TARDY2_SLA | 3 | START_PROP_P3_TARDY2_SLA | END_PROP_P3-TARDY2-SLA | CURVE_SHAPE_P3-TARDY2-SLA | AGEING_FACTOR_P3-TARDY2-SLA |

| 40 | Any Direction | P4_TARDY2_SLA | 4 | START_PROP_P4_TARDY2_SLA | END_PROP_P4-TARDY2-SLA | CURVE_SHAPE_P4-TARDY2-SLA | AGEING_FACTOR_P4-TARDY2-SLA |

| 41 | Any Direction | P5_TARDY2_SLA | 5 | START_PROP_P5_TARDY2_SLA | END_PROP_P5-TARDY2-SLA | CURVE_SHAPE_P5-TARDY2-SLA | AGEING_FACTOR_P5-TARDY2-SLA |

| 42 | Any Direction | P6_TARDY2_SLA | 6 | START_PROP_P6_TARDY2_SLA | END_PROP_P6-TARDY2-SLA | CURVE_SHAPE_P6-TARDY2-SLA | AGEING_FACTOR_P6-TARDY2-SLA |

| 43 | Any Direction | P7_TARDY2_SLA | 7 | START_PROP_P7_TARDY2_SLA | END_PROP_P7-TARDY2-SLA | CURVE_SHAPE_P7-TARDY2-SLA | AGEING_FACTOR_P7-TARDY2-SLA |

| 44 | Any Direction | P8_TARDY2_SLA | 8 | START_PROP_P8_TARDY2_SLA | END_PROP_P8-TARDY2-SLA | CURVE_SHAPE_P8-TARDY2-SLA | AGEING_FACTOR_P8-TARDY2-SLA |

| 45 | Any Direction | P9_TARDY2_SLA | 9 | START_PROP_P9_TARDY2_SLA | END_PROP_P9-TARDY2-SLA | CURVE_SHAPE_P9-TARDY2-SLA | AGEING_FACTOR_P9-TARDY2-SLA |

| 46 | Any Direction | P10_TARDY2_SLA | 10 | START_PROP_P10_TARDY2_SLA | END_PROP_P10-TARDY2-SLA | CURVE_SHAPE_P10-TARDY2-SLA | AGEING_FACTOR_P10-TARDY2-SLA |

Table 3- MSO SLAs related parameters - Tardy or within the Grace Period.

In forward scheduling scenarios, there may be cases where the Earliest Possible Start Time (EPST) falls later than the shop order's need date. In such situations, MSO prioritizes EPST as the key scheduling reference for the operation. The need date is used solely to define the schedulable window, based on the tardy scheduling period configured in the Finite Scheduling Basic Data page. Table 4 outlines the SLA types MSO applies in these scenarios.

| EPST> Need Date Situation (This is applicable for Forward Scheduling Scenario only) | |||||||

| PSO SLA Parameters | Shop Order Scheduling Direction | SLA_type | Shop Order Priority Category related MSO Priority Score | Relative MSO Advanced Parameters | |||

| # | start_proportion | end_proportion | activity_ageing_factor | curve_shape | |||

| 36 | Forward Scheduling | P0_FT_EPST_SLA | 0 | START_PROP_P0_FT_EPST_SLA | END_PROP_P0_FT_EPST_SLA | CURVE_SHAPE_P0_FT_EPST_SLA | AGEING_FACTOR_P0_FT_EPST_SLA |

| 37 | Forward Scheduling | P1_FT_EPST_SLA | 1 | START_PROP_P1_FT_EPST_SLA | END_PROP_P1_FT_EPST_SLA | CURVE_SHAPE_P1_FT_EPST_SLA | AGEING_FACTOR_P1_FT_EPST_SLA |

| 38 | Forward Scheduling | P2_FT_EPST_SLA | 2 | START_PROP_P2_FT_EPST_SLA | END_PROP_P2_FT_EPST_SLA | CURVE_SHAPE_P2_FT_EPST_SLA | AGEING_FACTOR_P2_FT_EPST_SLA |

| 39 | Forward Scheduling | P3_FT_EPST_SLA | 3 | START_PROP_P3_FT_EPST_SLA | END_PROP_P3_FT_EPST_SLA | CURVE_SHAPE_P3_FT_EPST_SLA | AGEING_FACTOR_P3_FT_EPST_SLA |

| 40 | Forward Scheduling | P4_FT_EPST_SLA | 4 | START_PROP_P4_FT_EPST_SLA | END_PROP_P4_FT_EPST_SLA | CURVE_SHAPE_P4_FT_EPST_SLA | AGEING_FACTOR_P4_FT_EPST_SLA |

| 41 | Forward Scheduling | P5_FT_EPST_SLA | 5 | START_PROP_P5_FT_EPST_SLA | END_PROP_P5_FT_EPST_SLA | CURVE_SHAPE_P5_FT_EPST_SLA | AGEING_FACTOR_P5_FT_EPST_SLA |

| 42 | Forward Scheduling | P6_FT_EPST_SLA | 6 | START_PROP_P6_FT_EPST_SLA | END_PROP_P6_FT_EPST_SLA | CURVE_SHAPE_P6_FT_EPST_SLA | AGEING_FACTOR_P6_FT_EPST_SLA |

| 43 | Forward Scheduling | P7_FT_EPST_SLA | 7 | START_PROP_P7_FT_EPST_SLA | END_PROP_P7_FT_EPST_SLA | CURVE_SHAPE_P7_FT_EPST_SLA | AGEING_FACTOR_P7_FT_EPST_SLA |

| 44 | Forward Scheduling | P8_FT_EPST_SLA | 8 | START_PROP_P8_FT_EPST_SLA | END_PROP_P8_FT_EPST_SLA | CURVE_SHAPE_P8_FT_EPST_SLA | AGEING_FACTOR_P8_FT_EPST_SLA |

| 45 | Forward Scheduling | P9_FT_EPST_SLA | 9 | START_PROP_P9_FT_EPST_SLA | END_PROP_P9_FT_EPST_SLA | CURVE_SHAPE_P9_FT_EPST_SLA | AGEING_FACTOR_P9_FT_EPST_SLA |

| 46 | Forward Scheduling | P10_FT_EPST_SLA | 10 | START_PROP_P10_FT_EPST_SLA | END_PROP_P10_FT_EPST_SLA | CURVE_SHAPE_P10_FT_EPST_SLA | AGEING_FACTOR_P10_FT_EPST_SLA |

Table 4- MSO SLAs related parameters - EPST>Need Date

Table 5 illustrates the SLA types MSO use to define three compression levels High, Standard, and Low in conjunction with the 'Compress Shop Order Lead Time' optimization goal.

| Scheduling with Compress (Activity_Group_SLA related Compress Level) | |||||||

| PSO SLA Parameters | Shop Order Scheduling Direction | SLA_type | Shop Order Priority Category related MSO Priority Score | Relative MSO Advanced Parameters | |||

| # | start_proportion | end_proportion | activity_ageing_factor | curve_shape | |||

| 47 | Any Direction | WIP-H-SLA | All | START_PROP_WIP_H_SLA | END_PROP_WIP-H-SLA | CURVE_SHAPE_WIP-H-SLA | AGEING_FACTOR_WIP-H-SLA |

| 48 | Any Direction | WIP-L-SLA | All | START_PROP_WIP_L_SLA | END_PROP_WIP-L-SLA | CURVE_SHAPE_WIP-L-SLA | AGEING_FACTOR_WIP-L-SLA |

| 49 | Any Direction | WIP-S-SLA | All | START_PROP_WIP_S_SLA | END_PROP_WIP-S-SLA | CURVE_SHAPE_WIP-S-SLA | AGEING_FACTOR_WIP-S-SLA |

Table 5- MSO SLAs related parameters - Compress feature

Table 6 below represents the standard multipliers that MSO is considering when prioritizing shop order operations based on the priority category of the shop order. The default values are determined based on results from internal test benchmarks.

| Parameter | Description | Type | Default Value |

| MSO_PRIORITY_SCORE_1 | Multiplier for MSO Priority Score 1 | Number | 0.3 |

| MSO_PRIORITY_SCORE_2 | Multiplier for MSO Priority Score 1 | Number | 0.45 |

| MSO_PRIORITY_SCORE_3 | Multiplier for MSO Priority Score 1 | Number | 0.5 |

| MSO_PRIORITY_SCORE_4 | Multiplier for MSO Priority Score 1 | Number | 0.7 |

| MSO_PRIORITY_SCORE_5 | Multiplier for MSO Priority Score 1 | Number | 1 |

| MSO_PRIORITY_SCORE_6 | Multiplier for MSO Priority Score 1 | Number | 1.25 |

| MSO_PRIORITY_SCORE_7 | Multiplier for MSO Priority Score 1 | Number | 1.5 |

| MSO_PRIORITY_SCORE_8 | Multiplier for MSO Priority Score 1 | Number | 2 |

| MSO_PRIORITY_SCORE_9 | Multiplier for MSO Priority Score 1 | Number | 3 |

| MSO_PRIORITY_SCORE_10 | Multiplier for MSO Priority Score 1 | Number | 5 |

Table 6- MSO Priority Score based on base value multipliers

Table 7 below lists the standard parameters used to define the general configuration of the scheduling dataset.

| Parameter | Description in detail | Type | Default Value |

| ACTIVITY_LIMIT | Maximum Number of Activities that can be Scheduled. The default value is determined based on results from automated test benchmarks. | Number | 35000 |

| BASE_VALUE_PER_HOUR | Fixed Base Value Per Hour | Number | 1000 |

| COST_OF_SPLIT | Incentive to Reduce the number of Splits of an Operation | Number | 2 |

| DELAY_COST | Delay cost for Split Model | Number | 1 |

| EXTEND_AVAILABILITY_MINUTES | No of minutes given to set as the availability when extending firm scheduled order | Number | 2 |

| LEADTIME_PART_STOCK_VALUE | Infinite Inventory Part stock to be planned to receive after the Lead-time completion when considering material constraints in PSO. This is defined based on the maximum integer limit in PSO. | Number | 214748.3647 |

| RESOURCE_PREFERENCE_WEIGHT | Preferred Resource Weight (0.5 to 1) | Number | 0.8 |

| RESOURCE_TYPE_COST_PER_HOUR | Cost per Hour on shift in Resource Type | Number | 20 |

| WSJF_REFERENCE | Weighed Shortest Job First Reference. This is considered as the incremental multiplier when defining base values for activities with due time interval (Need Date + scheduling offset) in the Past. | Number | 1.1 |

Table 7- MSO General parameters

All parameters on the MSO Advanced Parameters page can be modified by authorized users to meet specific business requirements, in accordance with standard PSO guidelines and the latest Scheduling Schema documentation. Recommended tolerance ranges are defined in the PSO documentation. Any issues resulting from inappropriate parameter changes are the sole responsibility of the user.

Prerequisites

- The scheduling optimization configuration must be properly set up to enable finite scheduling using MSO.

- All parameter changes will only be applied to upcoming finite scheduling actions executed via MSO.

- For sites configured with automatic MSO, a full site set-up must be performed again. This ensures that any template changes are reflected in the finite schedule.

System Effects

- Changes made for the standard parameters template will apply to all sites by default.