Workscope Ordering for Repair Routing

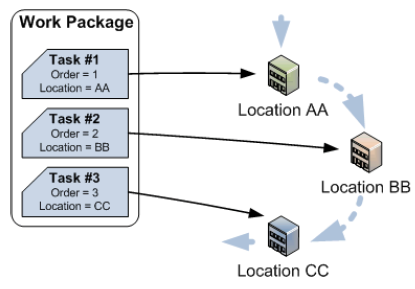

You can create a shop visit workscope that includes routine and estimated non-routine work, and you can use workscope ordering to ensure that the tasks in a component work package are completed in a specific order, and that each task is completed at a specific shop location.

Figure: Enforcing Workscope Order

You can enforce workscope ordering when creating a component work package, or you can use the Toggle Enforce Workscope Order button to enable workscope ordering after the work package is committed and the workscope is generated. You can turn enforce workscope ordering off, but if the task ordering was violated while the workscope ordering was not enforced, you cannot turn the enforce workscope ordering back on.

When a work package is committed, tasks that are not already assigned to a location are automatically assigned to a location with the capability for the task's work type within the work package supply location. See Automatic Assignment of Tasks to Shop Locations.

Each time a task is started, paused, or finished, Maintenix verifies that the task order is not violated. When tasks are batch completed or auto-completed, the workscope order is ignored.