Prorated life limits

While life limits on components are normally static, there are some cases where a component's life limit dynamically changes depending upon how that component is used.

An example of this can be found in engines. Some engines can be configured to run at different thrust ratings. For example, the CFM56 engine can be configured to run at 24k lbs thrust (for installation on B737-700) or 27k lbs of thrust (for installation on B737-800). In addition, there are certain modifications, sometimes known as tech insertions, that can be made to an engine that may alter its thrust and performance profile.

When an engine runs at different thrust ratings, the life limits of certain components within the engine may change. In particular, these components will typically last longer when the engine runs at a lower thrust rating.

To calculate how many cycles are remaining on each component, you need to take into account what percentage of the component’s life has already been spent, based on the thrust ratings it has undergone. You then use this history to calculate the current usage (or life) of the component prorated to the current thrust rating. The remaining life of the component is calculated based on the current thrust rating and the accumulated usage under one or more different thrust ratings. The life-limit corresponding to the current thrust rating will be used.

For example, if you are currently operating at 24k thrust rating (a lower thrust rating), then every previous cycle that occurred while the engine was at 27k will count as slightly more than 1 cycle. So if you previously flew 5000 CYCLES at 27k, they would be the equivalent of 7500 CYCLES at the current 24k.

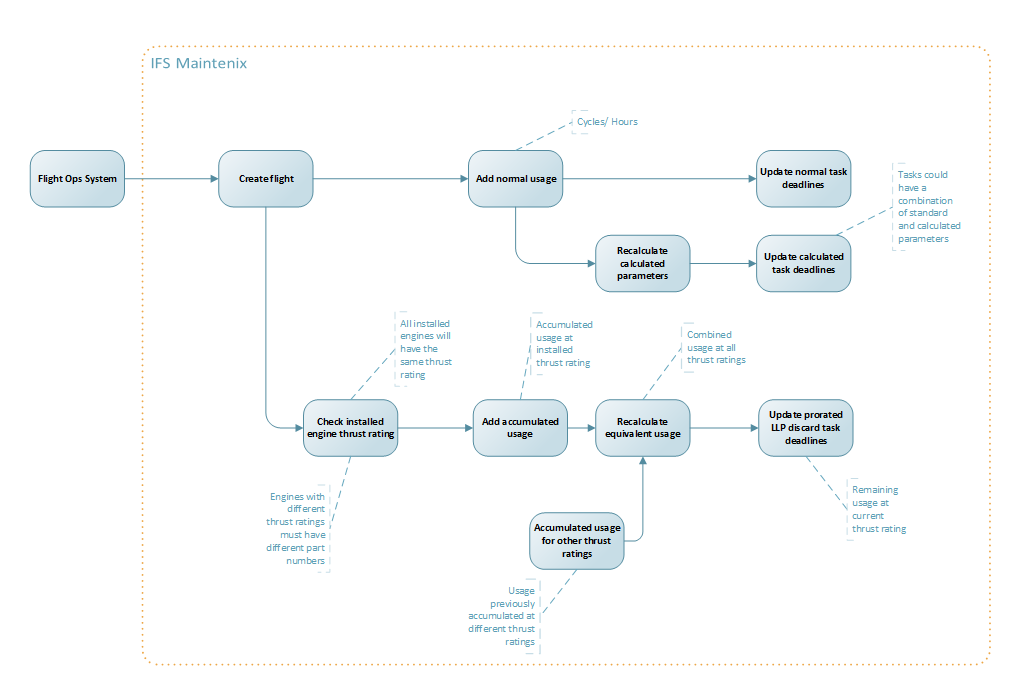

In Maintenix, life limits are enforced by tracking usage and creating discard requirements. To manage life limits at all thrust ratings in Maintenix, the following high-level steps are involved:

- Create a different engine part number for each thrust rating.

- Create accumulated usage parameters for each thrust rating to track the number of cycles performed at each thrust rating.

- Create calculated usage parameters for each thrust rating to allow Maintenix to calculate the prorated usage for components that have spent time at multiple thrust ratings.

- Create discard requirement definitions against each tracked component that is identified as being a prorated LLP.

Although this section uses examples for engines to describe this functionality, it is applicable to any sub-assembly type like APUs or landing gear.

The following figure displays the workflow of updating task deadlines with usage at thrust rating in comparison with normal usage.

Figure: Prorated LLP Workflow

For more information on the prorated LLP solution, see the related task below.

When you are creating or editing flights using the Maintenix Flight API, the prorated life limits solution can only work when you're using flights-2.0 messages. The flights-1.0 messages will not include accumulated parameters in the usage records, thus not providing you with usage at each thrust rating. For more information on flight messages, see the Maintenix Flight API Guide.