Manufacturing Scheduling and Optimization (MSO) solution optimizes the use of manufacturing resource constraints and in turn, creates finite schedule for the shop floor to execute production activities. The primary users of MSO are the Inventory Part Planners and the scheduling results are referred by Shop Floor Employees (i.e., Production Supervisors, Machine Operators, etc.). Production Schedule decides the overall sequence of manufacturing activities execution. Therefore, the most optimized schedule is given by MSO to achieve the defined business objectives of a manufacturing organization.

MSO solution uses Planning Scheduling and Optimization (PSO) solution as the scheduling and optimization engine. MSO creates an optimized schedule by scheduling activities within the most appropriate time intervals along the timeline while giving due consideration to the scheduling costs of the resources and other scheduling parameters, namely characteristic constraints, resource share capabilities of machine and labor resources, shop order priorities and working calendars and schedules.

The planners can decide the desired level of scheduling and optimization acceptance quality from the schedule as well as the maximum time the MSO solution should spend searching for a scheduling result. These settings are defined per Site upon the MSO dataset enablement. MSO is natively designed to remove or reduce the Number of Late Orders in either of the Scheduling Directions given in the Shop Order. This capability helps MSO to achieve timely demand fulfillment as much as possible.

In Manual Scheduling mode in the MSO solution, it starts working on finding an optimized scheduling solution as soon as it gets a scheduling request from the Planner. In Automatic Scheduling mode, it continuously performs the scheduling adapting to each and every change in demands, supplies and production environment. The scheduling algorithms in MSO work focuses on the optimized solution. As soon as the solution is reached, which may not be the most optimized, the system checks if the waiting time target or acceptance quality target has been exceeded. If yes, then MSO will immediately return the scheduling result to the end user. Based on the scheduling mode that the planner uses for the site, the optimization process may either continue or stop. In the case of “Manual” scheduling mode in MSO, it stops searching for a more optimized solution while in the “Automatic” scheduling mode, it continues searching for a more optimized solution until it finds the best solution for the Scheduling problem. Upon the completion of scheduling, the plan's quality displays in the 'Shop Order Scheduling Analysis' window and the 'Smart Manufacturing Planning Board' along with the scheduling results.

MSO creates finite schedules based on the manufacturing and shop order scheduling data. Therefore, it is essential to set the data that affects the shop order schedule before using MSO.

System Administrator should refer to detailed Technical Documentation for Scheduling Optimization and Machine Learning Configuration to set up PSO Configuration and the MSO profile in the PSO workbench.

The Following path in the TechDocs directs you to the MSO documentation:

Solution Manager User Guide->Automation & Optimization->Scheduling Optimization->Scheduling Optimization Business components->Manufacturing Scheduling Optimization (MSO)

For all other parameters default values are used. OpenIdAutority and OpenIdClientId are set based on the PSO client tenant IDs

If User expects optimization time accuracy of less than 5 minutes in the Schedule, it is advised to set the below parameter as well. This may affect the Performance of Scheduling Service.

Note: The user who initially enables the dataset is considered the owner of the dataset. Following dataset enablement, only users with admin privileges and the Dataset Owner can enable, disable, or delete the dataset.

Time Horizon (Days): Shop Orders with the Need Date in between the current time and count end date, counting this number of days, is considered for the Scheduling.

Note:- Shop Orders with Need Dates in the Past are also considered, considering a ten times negative interval from Site date. (i.e., Scheduling time horizon start date= Site Date - 10*Time Horizon (Days))

MSO datasets are scheduling optimization datasets in IFS, created based on a Scheduling Optimization Configuration.

These are the Hard constraints that the MSO Scheduling Service follows while generating the Scheduling Result.

Scheduling Rules in MSO strictly follow constraints when scheduling while achieving other business goals, such as:

MSO is natively designed to reduce the Number of Late Orders in either of the Scheduling Directions. This helps MSO to achieve timely demand fulfillments as much as possible.

The User can enable the Automatic schedule adjustment based on the Remaining time of the shop order operation. The remaining time is calculated based on the Quantity remaining to report. This setting can be used to re-adjust started or partially reported shop orders.

The User can advise the Scheduling service to consider the Project Activity Early Start and Project Activity Late Finish time range as a period to schedule for project activity connected shop order operations.

Operation blocks consideration in MSO is treated as a hard constraint in the Schedule.

On the Operation Blocks page, this site setting can be overridden with Schedule Operation blocks with MSO assistant. This assistant also supports defining proceeding and succeeding blocks, preferred resources, start/finish horizons for block scheduling, and auto-release of operations.

Note: This feature is released as a limited feature and works only with 24-hours shift working workcenter resources. i.e., Only with 24x7 calendar using resources.

These are the Soft constraints that the Scheduling Service follows while generating the Scheduling Result. Optimization Goals in MSO do not strictly follow rules when scheduling. They are the targets that scheduling engine try to achieve while strictly following standard scheduling aspects and Scheduling Rules.

By enabling this option, the Scheduling Service gives a higher opportunity to schedule passed due shop orders. This Higher opportunity to schedule is based on the Number of late days from the Need date of each shop order in the dataset.

By enabling this option, the Scheduling Service considers the Setup Matrices in the Finite schedule relevant to Shop Orders that are within the defined Selection Window time period.

- Refer to Activity Descriptions for Specify Scheduling Optimization Constraints and Modify Scheduling Optimization Constraints

MSO is natively designed to reduce the Number of Late Orders in either of the Scheduling Directions. This helps MSO to achieve timely demand fulfillments as much as possible.

In Forward Scheduling, the User expects to start production and execute the Demand fulfillment promptly. Forward scheduling is scheduling the first operation as soon as possible, followed by the second operation right after the completion of the first one, and so on until the final operation. With Capacity Constraint scheduling, forward scheduling means selecting the earliest possible timing as soon as materials and resources are available. Forward scheduling ensures that the schedule is realistic with respect to all constraints. It's important to note that forward scheduling doesn't guarantee the completion of scheduled orders within the stipulated timeframe. It might also lead to unnecessary early starts.

In this direction, the MSO schedule gives the highest opportunity for setting the EPST (Earliest Possible Start Time) of Shop Order Operations. If the EPST has already passed at the time of schedule generation, then the priority is given to the current time to schedule those orders as early as possible.

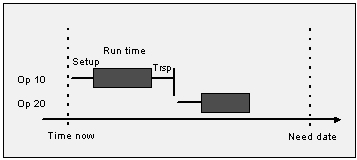

Figure 1 - Forward scheduling starts from the current date or EPST with the first operation

In Backward Scheduling, the User expects to start production and execute the Demand fulfillment as late as possible. This is also called Just in time (JIT) manufacturing. Backward scheduling is based on the Need date. The work must be completed before a certain date and time. To ensure that the work is scheduled prior to that date and time, the last task ending on the need date is scheduled first, then you can proceed with the second to last, and so on, until reaching the first operation. Backward scheduling ensures the timely completion of the order and avoids starting the order too early. This approach is most commonly used in food, dairy manufacturing or similar industries where the finished product has an expiration date.

In this direction, the MSO schedule gives the highest opportunity for the LPST (Latest Possible Start Time) of Shop Order Operations. If the LPST has already passed at the time of scheduling execution, the Shop order to which that particular operation belongs must become tardy. Therefore, those shop orders may not get the primary opportunity over the other future need-dated orders. The MSO is designed to reduce the number of late shop orders but not the lateness of a specific order.

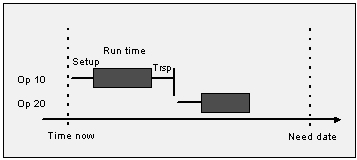

Figure 2 - Backward scheduling starts from the need date of the last operation

However for overdue shop orders, the User can give some higher opportunity in the Schedule by enabling the Prioratize Passed Due Shop Orders option under Optimization Goals on the Finite Scheduling Basic Data page. This feature gives a higher opportunity to schedule based on the Lateness of pass-due shop orders.

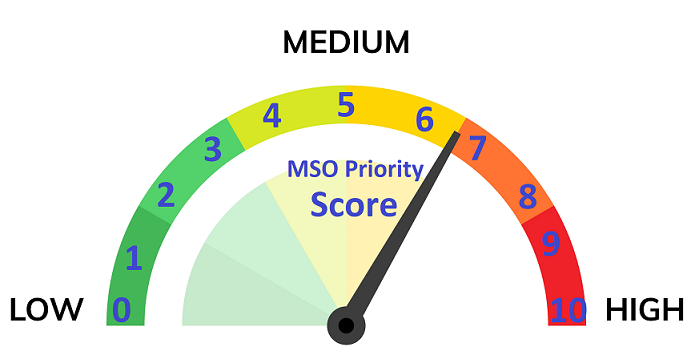

Priority Category in Shop Order is the key input to define the Priority of Shop Orders when scheduling in MSO. In Shop Order Priorities Overview, the User can define MSO Priority Score for each priority category. This priority score value can be defined as a number ranging from 0 to 10 based on business requirement. HShop orders with higher scores receive higher scheduling priority and push towards the EPST, or the Need Date based on the respective scheduling direction for each shop order. On the other hand, shop orders with lower scores receive less scheduling priority.

The Standard or medium priority score is set at 5. If there is no priority category defined in Shop Order, it is considered as MSO priority score 5 and gets a similar opportunity when scheduling.

Figure 3 - MSO Priority Scores

Machine Operations and Labor Operations are equally treated respectively when allocating resources in MSO.

Natively, in the MSO architecture, it considers both Machine and Labor operations with similar opportunities when allocating shop order operations. If a certain shop order operation has both machine and labor hours defined, the scheduling service considers it as a single booking that needs to be scheduled together, consuming the same time frame.

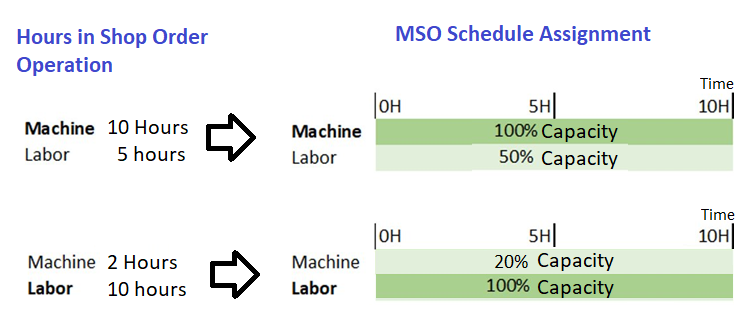

If machine hours and labor hours are not equal in a shop order operation, then MSO always considers the operation (i.e., machine or labor) that requires the Largest hours load to set a base duration and allocate it in full capacity (i.e., 100% capacity). The resource requiring the lower hours load allocates for the same duration at a partial capacity (i.e., less than 100%) booking based on the Load difference. This approach is considered for both Setup & Run operations and is calculated as separate transactions.

Example:-

Figure 4 - Machine or Labor: Largest time consuming constraint centric scheduling

When alternative resources available, e.g., two or more resources in a work center, the Preference is given based on the Resource efficiency. If there is a requirement to load a single resource, the Preferred Resource column can be set in the Shop Order Operation. Otherwise, MSO provides the most suitable position in the Timeline and makes a schedule result using a combination of resources based on their availability in respective work time calendars or HR schedules considering the Scheduling direction given in Shop Order.

MSO does not use a number of resources to perform a single labor or machine or tool operation. For example: If the labor Operation is 8 hours and Both Alain and Alex are in same respective labor class and Alain works the morning shift (8.00 AM to 12.00 PM) while Alex works the evening shift (1.00 PM to 5.00 PM). In this situation, MSO does not use both Alain and Alex to perform this operation. If Alain starts it, Alain must finish it consuming two days. MSO always focuses on assigning a single resource to a single operation.

If any partial operation report is done, then the specific reported resource is appointed to do the remaining part of that operation.

If Use HR schedule flag is enabled for persons in Manufacturing Labor Class, specific HR schedules are also considered by MSO including the Employee deviation days.

Note: MSO does not consider registered absences of the Employees.

If there are any tools connected to Shop Order Operation, then the required tool instances quantity is also allocated for the full duration of the shop order operation (i.e., Setup time + Run time). Tools availability is planned based on their respective calendars.

Infinite Workcenter resources are considered as a single resource with unlimited capacity.

If there are more than one infinite resource available to choose from (e.g., Infinite work center has 10 work center resources available), then MSO gives priority to the primary resource when scheduling the operations. The functional thinking on this approach is that if a particular resource has infinite capacity, then there is no use in distributing loads on multiple infinite capacity machines. Using a single machine may help to reduce the carbon footprint, energy, etc. This limited load distribution mechanism is natively supported in MSO when scheduling the operations.

If there is a partial operation report being done, then the same reported resource is planned to do the remaining part of the specific operation.

Infinite Capacity persons and tools are also considered in similar design thinking, using this limited load distribution mechanism.

Resource Share given in the Resource Share column in Shop Order Operation is considered by MSO when scheduling. This resource capacity share is applied to the resource capacity balance that results from the allocation of labor & machine capacity as described in the section above on Machine & Labor Operations Scheduling.

Decimal values given in labor Setup & labor Run crew size columns are also considered to set partial capacity booking during scheduling in MSO. This resource capacity share is applied to the resource capacity balance that result from the allocation of labor & machine capacity as described in the Machine & Labor Operations Scheduling section above.

Efficiency given in Shop Order Operations is considered when scheduling with MSO.

The operation efficiency affects only the run time, not the setup time. When the operation efficiency is set to less than 100% (default value), the remaining run time for the machine and labor is increased. This results in an increased value for the remaining manufacturing hours, which could affect the scheduled start and/or stop date of the operation. When you chang the operation efficiency, the change also affects the standard cost of the operation. Changing the operation efficiency can be done on specific operations, if there are running-in periods for a while, they temporarily affects the performance of the operation.

Efficiency given in Work center resource is considered.

Resource efficiency affects both run time and set up time. If the resource efficiency is less than 100% (default value), the operation is scheduled during a longer time period, because the set up and run time increase. Only scheduling is affected (start and finish date on the operation), not remaining manufacturing hours. Changing resource efficiency can be done if different machines (resources) operate in the same work center with different capabilities.

Preferred Resource information is considered as a preference when scheduling shop order operations.

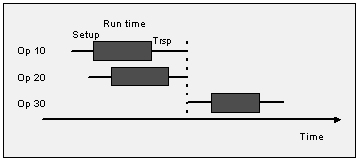

Transport time is considered when scheduling with MSO scheduling service.

If two operations are parallel, it means that they can be done totally independent of each other. The MSO scheduling logic tries to schedule them so that their output reaches the succeeding operation simultaneously.

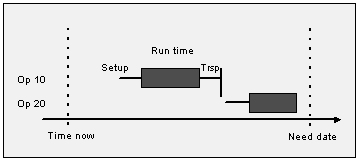

Figure 5 - Operations 10 and 20 are scheduled parallel

Operation Overlap is considered when scheduling with MSO scheduling service.

Refer to About Decription for Operation Overlap

A part's availability can be defined as Infinite, Finite (within a specific lead time), or Always Finite.

The parts with infinite availability do not constrain the schedule. For parts with finite availability, MSO checks for the required amount as it schedules.

The required amount is comprised of an existing supply or a new supply within the part's lead time. After the part's lead time, MSO assumes the part has infinite availability. For parts that always have finite availability, the required amount needs to be available to schedule an operation. As MSO schedules, it records the quantity and the date and time at which the material is consumed and produced.

Within the Scheduling horizon MSO is capable of planning the finite material supplies coming from other shop orders for child semi-assembled parts and accounting for it when scheduling the Shop Orders of final assemblies. This mechanism provides vast advantages to users who are not using complex order structures like DOP and still able to plan finite material supplies coming from their own sub-assemblies.

Obstructive Maintenance tasks for manufacturing resource objects are considered when scheduling with the MSO scheduling service. MSO considers the actual Work Task as a hard constraint that is booked for a defined time period from Planned Start to Planned Finish in the Work task. Remaining available time is used for the Scheduling of shop order operations.

Note: Maintenance Import is not a necessary work task to consider for MSO Finite scheduling since this directly refers to the Work tasks from Maintenance management. Manually created Maintenance tasks such as Resource Breaks are not considered for the MSO finite schedule.

Refer to About Description for Smart Manufacturing Planning Board

i.e., Shop Order Infinite Schedular is generally tiggered only for changes related to Shop order operation workcenter. However, when MSO is enabled, changes related to Setup & Run Labor Class, Setup & Run Labor time, Setup & Run Labor crew size, Setup & Run Labor qualification profile, Manufacturing Tools and number of instances will also trigger the 'Shop Order Infinite Scheduler' to maintain the Track of up-to-date information respect to the Shop Order operation 'Scheduling status' information.