Block definitions

Requirement definitions that should be completed together can be grouped in block definitions. Using blocks facilitates the scheduling of the large number of maintenance requirements that aircraft and other assemblies often have.

You can create blocks for daily requirements such as overnight checks, or for heavy maintenance visits that can have hundreds of requirements. Block definitions are always associated with a configuration slot, not a part number. Blocks are generally created the root level of the assembly.

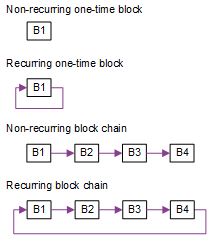

Figure: Recurring and non-recurring block and block chain definitions

In a block chain, the same requirement can be added to multiple blocks. You can use block chains to divide maintenance visits into phases, or to equalize the workload by spreading requirements that have varying intervals across the blocks in a chain.

- Create the block definition. Optionally add technical references, attachments, and (complies, opportunistic, replaces, or supersedes) links to task definitions.

- Add scheduling rules and applicability to the block definition as you do for other task definitions.

- Assign requirements to the block or blocks.

- Approve, activate, initialize the definition as you do for other definitions.

Blocks can be modified, and locked to prevent modification.

If you move one block that is part of a block chain to a different configuration slot, delete the block, or make it obsolete, all the other blocks in the chain are also moved, deleted or made obsolete. Also, when you active a block chain you activate all blocks that are included in the chain.