Location hierarchies

You create a hierarchy of locations to link the various parts of your organization and enable the workflows that you use.

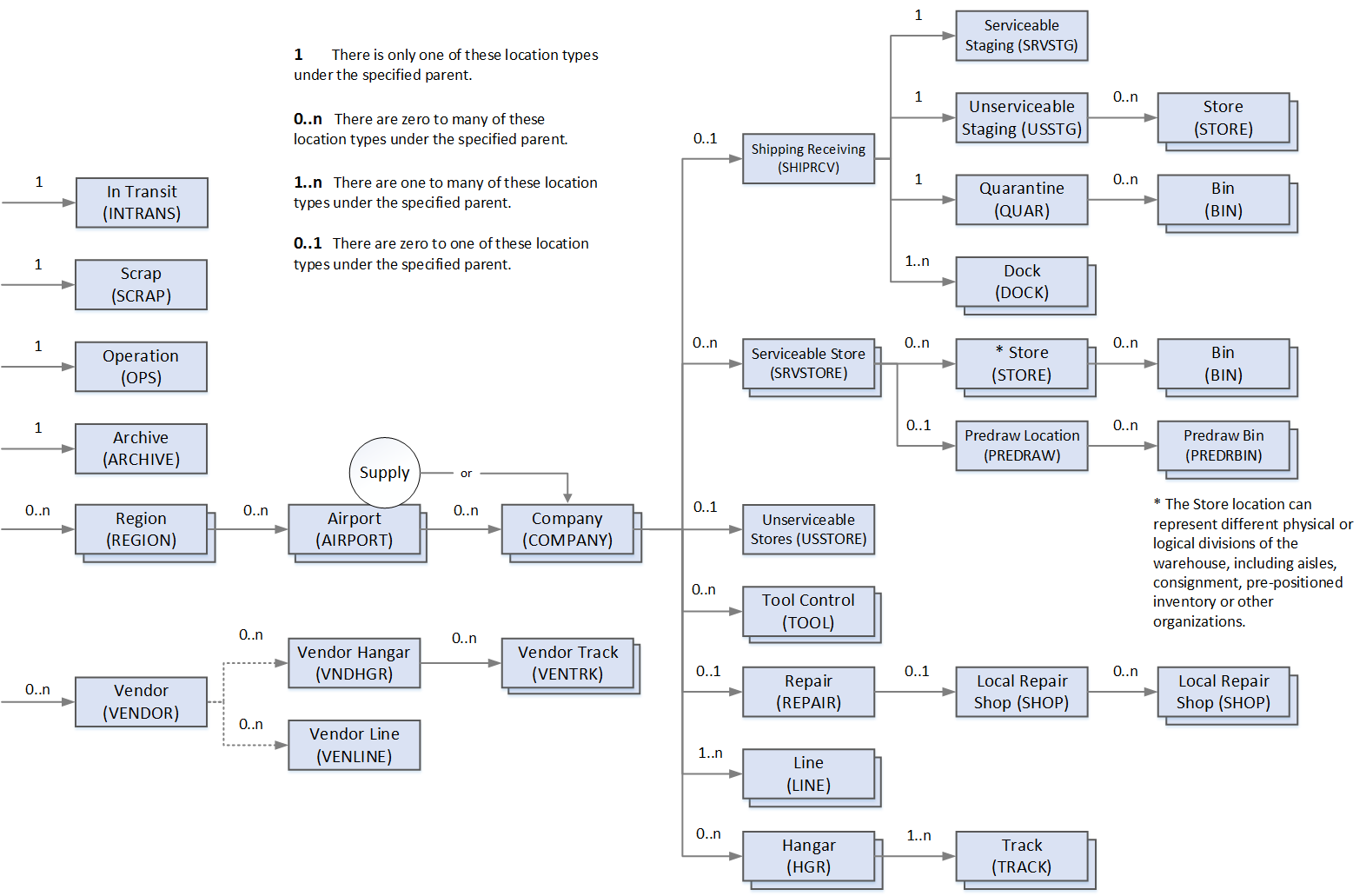

At the top of the location hierarchy, you can have an airport or a region with sub-locations underneath. You can then create further sub-locations to represent hangars, tracks, repair shops, and more. Some locations are mandatory and others are optional. See the location description topics for more information.

You can create more than one location hierarchy. You might want to do this if your organization spans several airports.

Figure: Example of a Maintenix location hierarchy

In a Maintenix location

hierarchy:

- Only one location in a hierarchy can be marked as a Supply location—usually an Airport or a Company location. If the Airport is marked as a Supply location you might not need the optional Company location in your model. Alternatively, your model can include multiple parallel companies, each one marked as a Supply location, with independent hierarchies under them.

- Vendor (VENDOR) locations are associated with the Vendor Hangar (VENHGR) and Line (VENLINE) locations, but are not linked in parent-child relationships.

- The Vendor Hangar, Vendor Track, and Vendor Line locations are also used by the Long Range Planner (LRP) application. If you are outsourcing work and shipping materials to an MRO, you can create a location hierarchy to model this. See Represent an MRO in a hierarchy.

- Automatically issuing inventory items for outsourced maintenance can be controlled by enabling or disabling Auto Issue Inventory for Vendor Line and Vendor Track locations.

- Stores locations under Unserviceable Staging can be used to separate SoS parts or other categories of parts.

- To use auto-put-away, associate each part with a maximum of one bin (usually in Serviceable Stores). In organizations with multiple, specialized local repair shops: to route work to the shops your hierarchy includes the specialized shops as children of a parent SHOP location. Component work packages are scheduled to the parent level SHOP location.