Part and task incompatibilities

By default, Maintenix assumes that all parts are compatible with all other parts and that all part numbers can be installed on an assembly regardless of what tasks are completed or open on the assembly. In practice, some parts can only be installed in conjunction with other specific parts, or when a task (such as a modification) has a specific status.

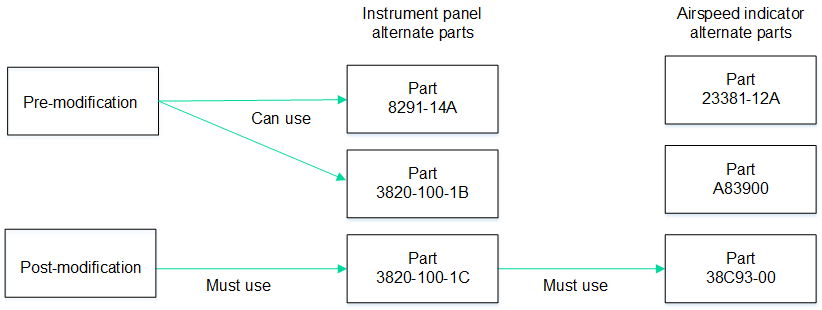

- Only the latest version of the airspeed indicator can be installed on the latest version of the instrument panel.

- The older versions of the airspeed indicator can't be used with the new instrument panel, but the latest version of the airspeed indicator can be used with older instrument panels.

Figure: Compatibility scenario

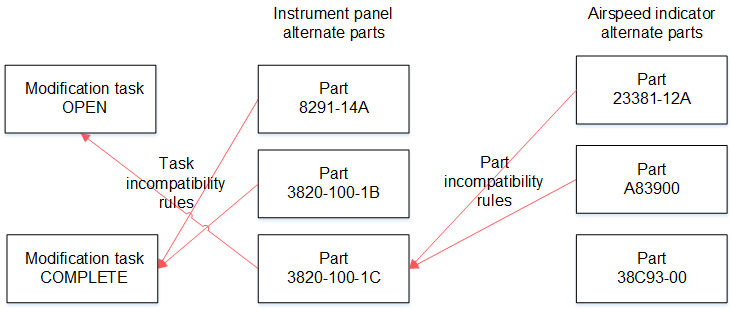

To model this in the Maintenix baseline and ensure that only compatible parts are installed, you create part or task incompatibility rules to explicitly define combinations of parts and tasks that can't be used together. Incompatibility rules create exceptions to the default behavior. The diagram below shows the incompatibility rules that are required for the scenario diagram above. All other combinations of parts in the instrument panel and airspeed indicator part groups are compatible and can be installed together.

Figure: Incompatibility rules in Maintenix

Part incompatibility

Part incompatibility rules specify which part numbers, within groups of alternate part numbers, are not compatible with other part numbers. You can specify incompatibility rules for parts within the same part group or in different part groups. Maintenix assesses part incompatibility when parts are reserved, issued, and installed.

Maintenix supports part incompatibility rules only between part numbers with the tracked inventory class.

- Configuration hierarchies are built with root, system, sub-assembly, and tracked classes of configuration slots.

- A root configuration slot is an aircraft or assembly.

- Sub-assembly and tracked slots can have multiple positions.

- Configuration slots have part groups.

- Global part incompatibility

- Incompatibility is assessed against all other parts installed under the highest parent assembly (root configuration slot) of the installed part. If the part is installed on a sub-assembly that's installed on an aircraft, then the aircraft is the highest assembly. If the part is installed on a loose assembly, such as an engine, the highest assembly at that time is the engine.

- Assembly position part incompatibility

- Sub-assembly class configuration slots can have multiple positions. Incompatibility is assessed up to and under the sub-assembly configuration slot position that a part is installed on.

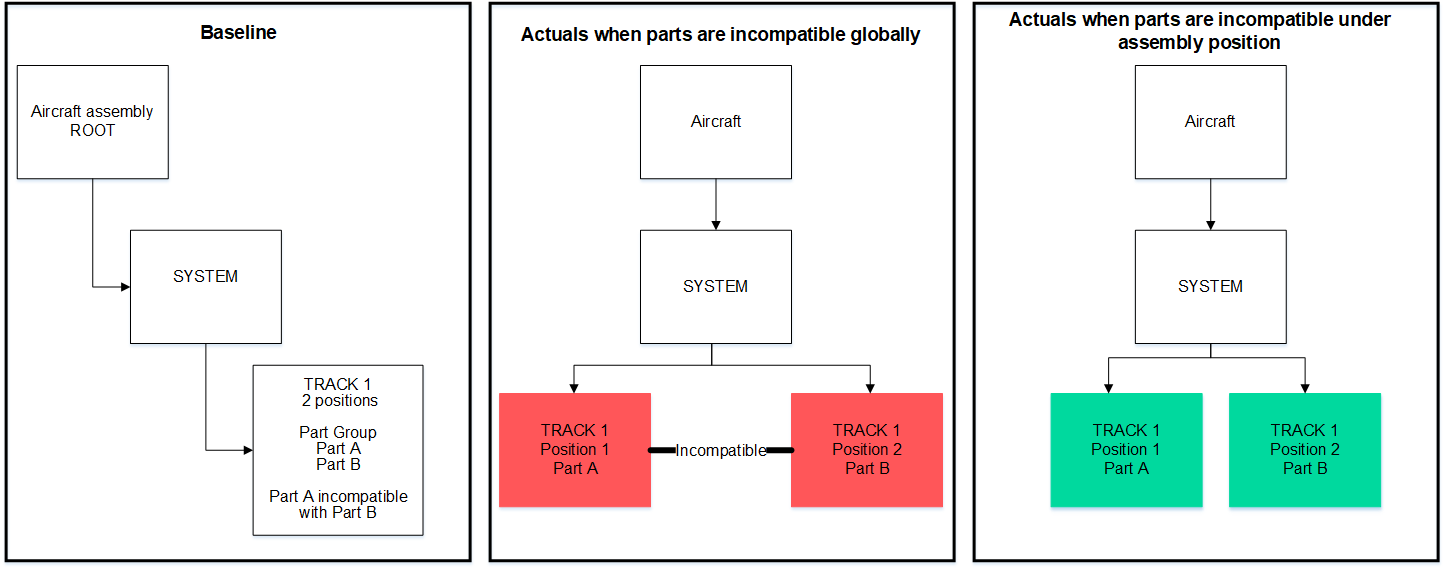

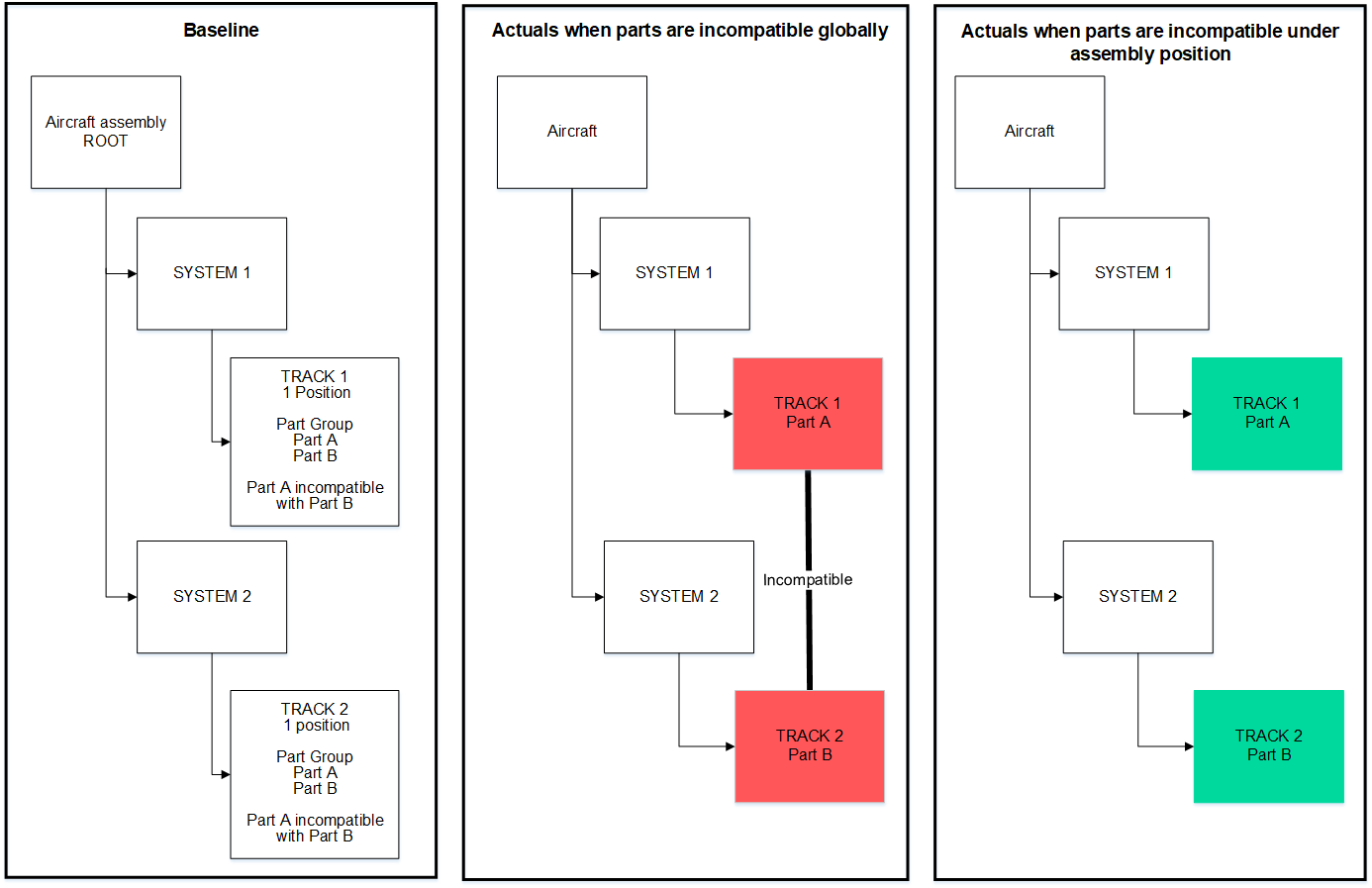

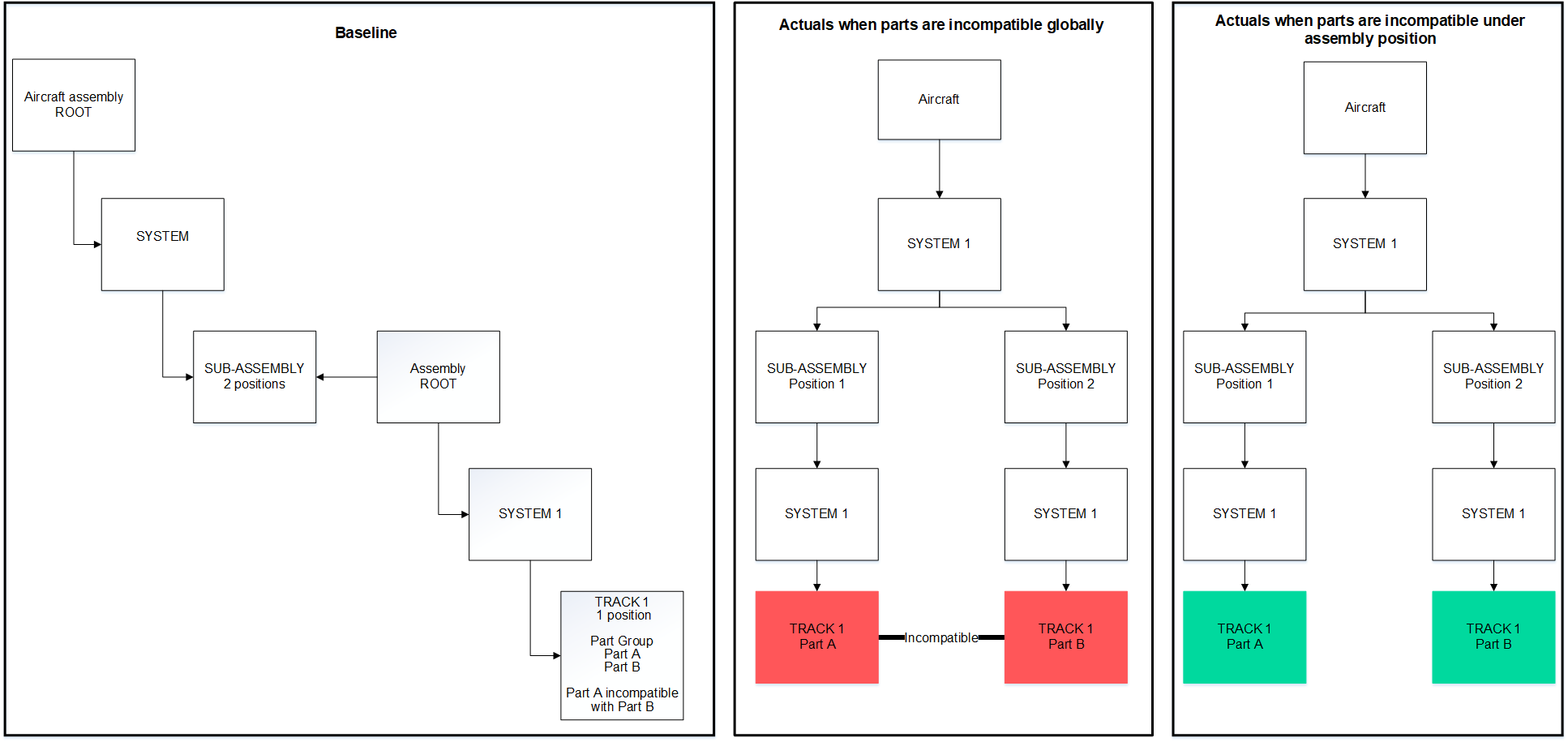

The following examples show the difference in part compatibility outcomes when an incompatibility rule is created for Parts A and B with the Global type and with the Assembly Position type.

- If the incompatibility rule is the Global type, Part A and Part B are incompatible.

- If the incompatibility rule is the Assembly Position type, Part A and Part B are compatible.

Figure: Part incompatibility example 1

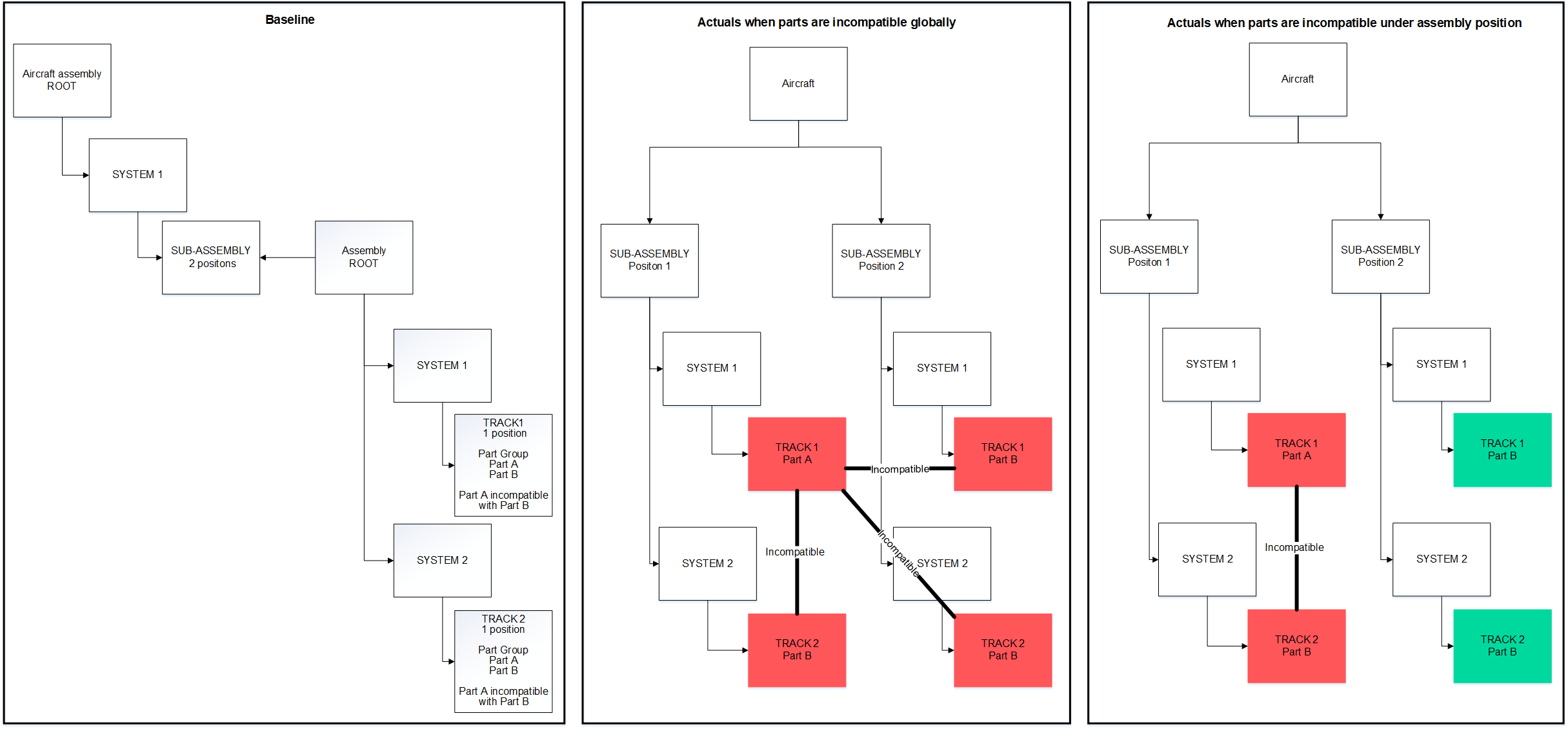

- If the incompatibility rule is the Global type, Part A and Part B are incompatible.

- If the incompatibility rule is the Assembly Position type, Part A and Part B are compatible.

Figure: Part incompatibility example 2

- If the incompatibility rule is the Global type, Part A and Part B are incompatible.

- If the incompatibility rule is the Assembly Position type, Part A and Part B are compatible.

Figure: Part incompatibility example 3

- If the incompatibility rule is the Global type, Part A and Part B are incompatible. Only one part or the other can be installed anywhere on the aircraft.

- If the incompatibility rule is the Assembly Position type, Part A and Part B are incompatible when installed under the same assembly position.

Figure: Part incompatibility example 4

In the examples, the root assembly is an aircraft, but if an engine assembly is loose, the root and highest assembly at that time, is engine sub-assembly.

Complex tracked part incompatibilities

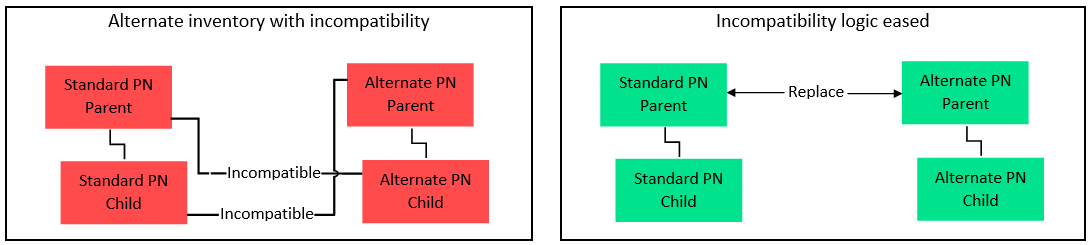

The Part Incompatibility logic is eased when complex tracked parts are reserved, issued and installed.

Consider alternate tracked parts that are configured in the same part group such that child components installed on them are incompatible with each other's parents. Example: Emergency escape slides on aircraft: the slides are interchangeable, but the individual cartridges installed on the slides are not interchangeable.

When an installed inventory is being replaced with an alternate inventory that is incompatible at the child level or below, Maintenix allows users to add install part requirements for the alternate inventory when the incompatibility is on or under the configuration slot position being replaced. The same logic applies for reserving parts manually as well as automatically and completing installations.

Maintenix also allows users to proceed with inventory creation when a sub-component standard part is incompatible with the parent, in many scenarios including when receiving a shipment, turning in an inventory, and capturing the work of removing or installing an inventory.

Task incompatibility

Task incompatibility rules specify which part numbers within groups of alternate part numbers cannot be installed based on the specified task and task status. When you create these rules, you select a task definition and specify whether the part number is incompatible when the task is complete or when the task is open. In the case of a modification, some parts in a part group will have a rule for when the task is open while other parts in the same part group will have a rule for when the task is complete.

Some pre-modification and post-modification incompatibility rules can be modeled as one-way interchangeability.

Maintenix supports task incompatibility with tracked and serial-controlled parts.